Complex set-up operations, multiple topside systems and interfaces, and arduous workflows; these are all now in the past. Sonardyne’s Fusion 2 survey software combines intuitive workflows with faster, more flexible INS, LBL and Sparse LBL aided INS operations - all from a single system.

Since surveyors and subsea construction operatives took their first steps into the US Gulf of Mexico, followed by the harsh waters of the North Sea and beyond, the industry has been on a learning curve. From taut wire through to today’s digital signalling architectures, systems and methodologies, the industry has evolved. Developments in signalling technology have driven significant advances – Wideband digital signal technology brought survey and construction operations out of the “stone age” and enabled true life-of-field navigation across a whole field of developments. A manageable number of acoustic transponders with digital signals could now offer both long (several kilometres) and highly accurate (millimetric) ranges. The development of Sparse LBL techniques, thanks to the use of inertial navigation systems (INS) like our SPRINT, introduced the concept of deploying fewer transponders on the seafloor, reducing survey times.

These evolutions have made operations faster and more accurate, but often also more complex; INS-aiding brings cost saving advantages but requires the need to interface INS and LBL software and hardware systems. Switching between the two, or making them work together, can be time-consuming.

Sonardyne has been providing LBL acoustic positioning software, supported by generations of our trusted Compatt transponder, for 40 years since the first unit was sold in the late 1970s. Since 2006, we’ve also been developing INS solutions. Taking the learnings and experience built up in both technologies over this time, and through listening to our customers, our software engineers have written, from the ground up, a new, single, powerful, multi-user capable system. From it, surveyors and construction personnel can do all their LBL and INS operations in any combination they want, faster, easier, and with less hardware and fewer interfaces – it’s called Fusion 2.

Wideband 3

A key enabler for Fusion 2 is the latest evolution of our Wideband signal architecture – Wideband 3 – which not only offers faster tracking updates, at 1Hz LBL tracking, but also provides combined telemetry and position updates in the same signal. This means tracking is no longer interrupted when sensor data (attitude, heading, depth, etc.) is required. By combining ranging and telemetry data, Wideband 3 accelerates update rates by a factor of 10. Combined with our 6+ hardware, further capabilities are unlocked. When Compatt 6+ ranges are received by an ROV mounted ROVNav 6+ transceiver, Fusion 2 starts calculating its position immediately, instead of waiting for all the array ranges to come in before sending the data to Fusion and on for processing. This means operators know the position of their ROV faster.

|

|

|

Real-time SLAM

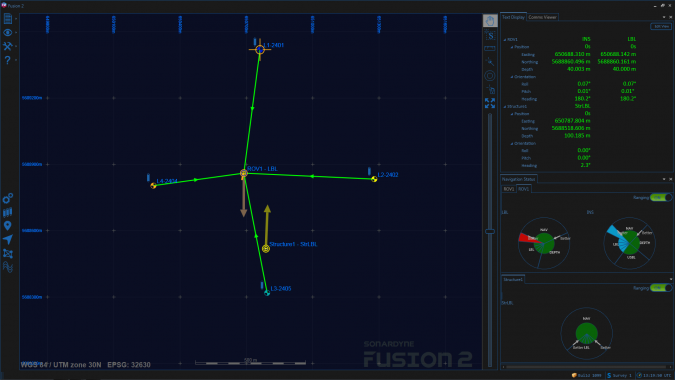

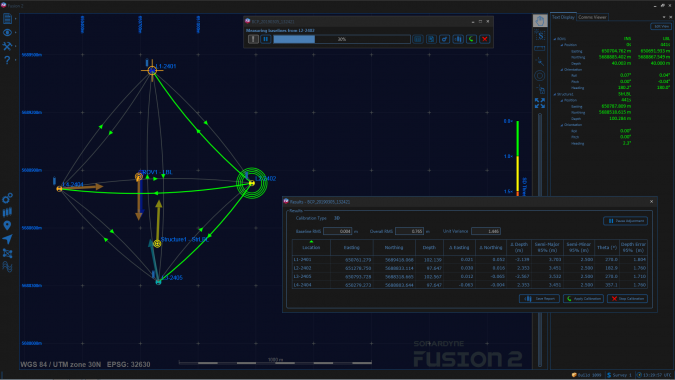

In Sparse LBL, the SPRINT INS on an ROV can take ranges from a single transponder and, because it knows its own movement, can calculate its position relative to the transponder. The key is knowing where in the real world that transponder is. Unlike full LBL transponder arrays, a single transponder cannot be quickly LBL baseline calibrated and, to date, has required to be individually boxed-in by expensive vessels. Fusion 2 removes this box-in requirement through the addition of real-time SLAM calibration. To enable real-time SLAM, our software engineers developed a set of algorithms to run in the SPRINT INS. This means, using raw ranges from Compatt 6+ transponders, Fusion 2 can compute their position without needing to box-in or baseline calibrate. Fusion 2 manages the whole process in real time so, as soon as you achieve the navigational accuracy you need for your project, you can stop calibrating, start tracking and get to work. Fusion 2 can also SLAM calibrate, initialize and start tracking with ranges from just a single seabed reference beacon, making operational start-up faster and simpler.

Full LBL

For full LBL array operations, the faster ranging and telemetry updates brought by Wideband 3 de-stresses and de-risks mobile Compatt tracking. With sensor data embedded with the range data, you get fast uninterrupted tracking. Sound velocity data can also be accessed without interrupting tracking, further improving confidence in the reliability of position updates.

The previous lengthy workflows, which involved selecting, adding and then giving transponder locations, have been replaced by a simple process in an intuitive and adaptable user interface (UI). Fusion 2 now separates locations and transponders – this enables you to have multiple transponders in a single location, such as a multi bucketed tripod, and swap and change transponders in and out of locations, as does happen over field life-cycles. Then, during an operation, surveyors can dynamically select and change seabed acoustic transponder references during navigation, instead of having to stop and reconfigure them. Once tracking, surveyors can also easily track if they’re within their set positional accuracy limits through the UI.

Fusion 2 has also been built to use Earth-centred Earth-fixed (ECEF) coordinates for positioning and calibrations, which means grid scale factors are not an issue. With the Sonardyne’s iWand, Compatts being readied on the back deck can also be given their locations prior to deployment – they’re simply loaded into an iWand wirelessly from Fusion 2, then sent to the transponders wirelessly on deck – so you know their status before they even hit the water. This all makes Compatt inventory management easier and from one place. Furthermore, acoustic LBL and INS surveys can be configured ‘in the office’ before mobilisation.

|

|

Flexibility

Because of the way the system has been designed, users have complete flexibility in how they want to operate; they can let the system do the work for them, or tailor their operations how they want. A user can run everything from USBL INS operations to full LBL surveys and everything in between.

Multiple computations can be run easily, to compare different set-ups, to see which one is best suited for a particular operation. Then, when using the UI, as well as being able to easily select and place the windows you want to see for any particular operation (and save these for future reference), operators can chose modes suited to their own environment (i.e. night time or day time screens to make viewing easier in a dark cabin or in full daylight). Fusion 2 also has a remote interface for monitoring position data, and in future, more processes and workflows will be automated, and we will be looking to enable smarter integration with survey systems.

Fusion 2 also supports use of our SPRINT 300 for LBL INS, which means lower start-up costs. And with Compatt 6+ able to support five users at the same time, simultaneous operations are less challenging on resources.

One System, One Hub

To further reduce hardware requirements, Fusion 2 was developed so that it works through our Navigation Sensor Hub (NSH). This is the same hub used for our Ranger 2 USBL system, so operators need fewer systems (just one PC, one sensor hub and one cable between them) and fewer systems in their inventory.

The full Fusion 2 package will be launched at Ocean Business, Southampton, UK, in April 2019. There, we’ll be showing off its capabilities during live, daily demonstrations. If you’re unable to attend the show, get in touch with us through social media, our website or your local office to find out more about our 2019 experience events.