A recent survey of the inland port on the island of Helgoland demonstrates that choosing the right vessel for offshore surveys can save time and money, especially when the only alternative is to transport survey vessels to the project site by ship.

Located 69 kilometers (43 miles) by sea from Cuxhaven at the mouth of the River Elbe, Helgoland is the only German island territory not in the vicinity of the mainland coastline. Consisting of two islands that were once joined before a storm flood destroyed the land connection in 1721, Helgoland has been a popular holiday resort since it was returned to German sovereignty in 1952 following its post-World War II years under British control.

Many of Helgoland’s roughly 1,400 residents have worked in or supported the tourism industry, but from a peak of 10,000 visitors per day, the island now welcomes around 2,500 every day (prior to COVID-19). New perspectives for port use, business and leisure are easing Helogland’s dependence on tourism. Following early enquiries by operators in 2009, the focus has been placed on accommodating the offshore wind farm sector to secure a long-term positive outlook for island residents.

Ports Expansion Project

With the prospect of attracting major new companies to the island and retaining them for decades to come, the municipality of Helgoland started an extensive expansion project for its ports in 2010. The goal was to prepare them to support the operation and maintenance of offshore wind farms in the German North Sea, especially at the HelWin cluster, which is located about 35km from Helgoland.

Hafenprojektgesellschaft Helgoland mbH (HGH) was created in 2010 to manage the Helgoland ports improvements. Founded by the Wirtschaftsförderungs- und Entwicklungsgesellschaft des Pinneberg mbH (WEP) and the municipality of Helgoland, the organization aims to overcome the technical and logistical challenges that construction work on an offshore island entail. HGH is responsible for renovation, modernization and conversion in the various ports and port areas on the island, with work split into several large construction phases, each of which is divided into smaller sub-projects.

A huge amount of work has been done over the past decade. Preparation for building of the southern port area was completed in 2013 alongside the planned new roads to service it, while the building of a new heliport was completed in 2015. Improvement works to the inland port, which is located to the south-east of the island, are also ongoing. The 125-metre-long south-east bank of the port had been in a very poor condition for many years, with partial sagging forcing it to be closed, which significantly restricted the inland port’s usability as a multifunctional port.

The renovation of the quay on the south-east bank became one of the main goals in the inland port improvements. In preparation for the quay construction, the old south-east bank was dismantled and the stability was restored with a heavyweight wall installed in the quay.

Post-construction Survey

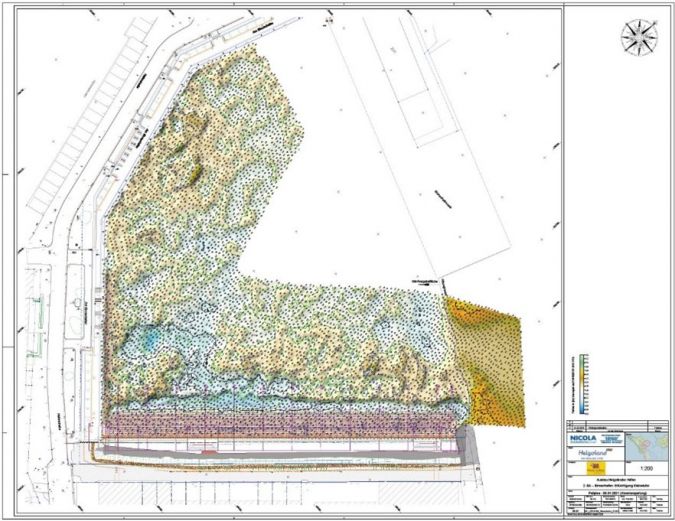

Work on the quay facility was completed in 2020 and a post-construction project survey was ordered to verify its quality and accuracy. Hamburg-based marine survey company Nicola Engineering was tasked by HGH’s sub-contractor Colcrete von Essen to carry out the survey in January 2021.

Nicola Engineering had already completed 12 commercial survey projects on or around Helgoland over the last 40 years, which was an important consideration for the contract award. This latest campaign would however prove to be different, as it was an early job for Nicola Engineering’s new sister company, Nicola Offshore.

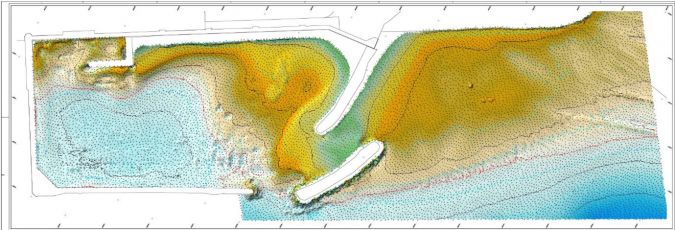

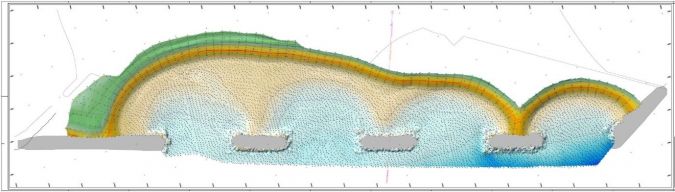

Nicola Engineering’s previous survey on Helgoland was a dredging report (with accompanying land survey on the beach) on the smaller Helgoland Dune Island in 2019. While the survey was successful (Figs. 1 and 2), the logistics surrounding it highlighted the challenges of acquiring accurate marine data in an offshore location, with the problem boiling down to the time and cost inefficiencies of short surveys with long transit times.

Helgoland itself has minimal local marine survey capabilities, so the boats and expertise had to be shipped in. In this case, Nicola Engineering loaded its survey boats onto a transport vessel from Cuxhaven, after driving with trailers from Hamburg. The added time of this was compounded as the transport ship’s schedule meant that the survey boats would need to be sent to Helgoland early and left unused while waiting for the return leg after the project.

At the time, no viable alternative was available so the use of commercial transport ships to bring in the survey vessels was a necessary but less than efficient approach to acquiring the high-quality data required by the client. This led to Colcrete von Essen and HGH agreeing to use a new type of survey platform for the Helgoland inner port survey.

The platform in question was the Nautical Explorer, a 12-metre-long, 4.8-metre-wide purpose-built high-speed survey vessel owned and configured by Nicola Offshore with a draft of just 0.6 meters. Offering a top speed of 44 knots and excellent seakeeping abilities, Nautical Surveyor has been designed to get the Nicola Offshore team to offshore survey sites quickly and safely.

Already in place in Cuxhaven, it was less than an hour’s ride to Helgoland on Nautical Explorer this January. Prior to mobilization, Nicola Offshore had tasked hydroacoustic equipment specialist Subsea Europe Services GmbH to provide its integrated Hydrographic Survey System (iHSS), which gave the ability to acquire data to the new IHO S-44 Exclusive Order standards. The iHSS is a ready-to-mobilize solution based on multibeam echo sounders made by R2 Sonic and including all the necessary equipment, such as a workstation, software, inertial navigation system and flexible mounting.

Equipped with its state-of-the-art hydroacoustic system and two Yamaha 350 V8 outboard engines, the team on Nautical Explorer was able to complete the required post-construction survey (Fig. 3), including transit from Cuxhaven to Helgoland and back, in just seven hours.

Compared to the cost of the non-productive time with survey boats sitting idle during the 2019 Dune Island survey, the use of a fast vessel provided immediate and tangible savings.

Offshore Wind Farms

The use of fast survey vessels is also enabling a more agile approach to surveying at offshore wind farms. In fact, the catalyst for the official opening of Nicola Offshore in March 2021 was a small Nicola Engineering project in 2020. The team was tasked by an offshore wind service company to carry out a ‘rapid survey’ to locate and identify a small feature on the seabed in the North Sea.

Rather than wait for a large, slow commercial survey vessel to become available in the area or ship one of its Hamburg-based platforms in, Nicola Engineering turned to Dutch shipyard and charter company ProMarine BV to mobilize a small, fast survey boat with relevant offshore permits already in place.

That boat was Nautical Explorer. The unique combination of the iHSS, a fast, class-approved survey boat and skilled operators met the requirement for a high-resolution multibeam echo sounder to survey the target – a small subsea feature approximately 1 metre in length – in water depths exceeding 30m.

The project was completed within two days of Nicola Engineering receiving its brief and the survey was finished in a single day out of a small port in the Netherlands. Mobilization and calibration of the iHSS on Nautical Explorer took about two hours. The team successfully located and identified the feature quickly and at a considerably lower cost than would be involved in shipping a survey boat out to the site.

The Helgoland inland port survey highlights identical challenges to marine data acquisition at offshore wind farms. The distances involved are similar, so the ability to safely transit using ready-equipped and configured fast survey vessels rather than have a boat shipped in separately provides much more agility for the fast-growing North Sea wind sector.

This was the background that led to Nicola Offshore to develop its niche services, including post-dredging reports, unexploded ordinance (UXO) and object search surveys, as well as cable routing surveys for offshore wind farms.

Expanding the Fleet

Recognizing the growth in demand for such unplanned surveys, and that its unique approach to logistics is the solution to enabling a more agile and cost-effective service, Nicola Offshore is rapidly expanding its fleet.

An extensive new-build programme is supported by the fact that Dutch workboat manufacturer ProMarine BV, along with Nicola Engineering, is part owner of Nicola Offshore. ProMarine currently has two new-builds for Nicola Offshore in progress, having delivered the new 14-metre-long and 5.2-metre-wide survey catamaran Nautical Surveyor as the second vessel in the fleet this summer. Nautical Inspector, an identical vessel to Nautical Explorer based on the PROCAT 1200 OBC design, also became operational in October 2021.

Nicola Offshore has selected a 2x150hp OXE diesel outboard instead of the same petrol Yamaha engines as on Nautical Explorer, to give clients an option of reduced fuel usage and CO2 emissions, with the sacrifice of some speed. It will be fully rated for offshore operations, however. Additionally, two further PROCAT 1200 OBC design vessels are in the pipeline for construction in 2022.

The final vessel for delivery in 2021 will be a unique addition to the Nicola Offshore fleet. Nautical Discoverer is a dedicated fast response vessel for UXO and object search projects. It features a hydraulic A-frame for mounting diverse instruments, which can be lowered for surveying and lifted for rapid transit. It’s due for service before the end of the year.

While speed and agility are the drivers behind Nicola Offshore’s fleet, a recognizable aspect of all the vessels will be the inclusion of multibeam echo sounder solutions based on the iHSS from Subsea Europe Services. Already proven to deliver the quality of data needed, the configuration flexibility and fast deployment inherent to the iHSS concept adds another layer of agility, while the use of R2 Sonic multibeams ensures that Nicola Offshore’s data specialists can deliver the highest quality finished products to its clients.

And while a high-quality end product is the goal, how you get to that point can be just as important. This is why, when it comes to ad hoc surveys at offshore wind parks, speed really does matter.