Anti-biofouling Protection Film: MARINGLIDE™

Newly developed antifouling solution

Nitto Denko Corporation (hereafter: Nitto) has developed a new anti-biofouling protection film to prevent the build-up and growth of biofouling. The film is ready-to-stick and its specially treated surface can prevent microorganisms from settling and taking root on it for a long time.

Biofouling is a critical issue that affects a lot of subsea instruments. For instance, if underwater sensors get covered in microorganisms, the system effectiveness might decrease, and barnacles attaching and growing on sensors or other active instrument areas can disrupt the quality of the measurements. In addition, biofouling involves a lot of physical and financial effort to clean the instruments, while the use of high-pressure water jets, scrapers, brushes or chemicals can permanently damage the sensitive sensor area. Biofouling might also affect the visibility range of optical instruments, requiring frequent and expensive physical maintenance.

Nitto’s original patented technology can reduce all sort of biofouling issues without harming sea life: the film is biocide-free and eco-friendly. It can be attached and removed by hand and disposed of as inert plastic after use.

About Nitto Anti-biofouling Protection Film: MARINGLIDE™

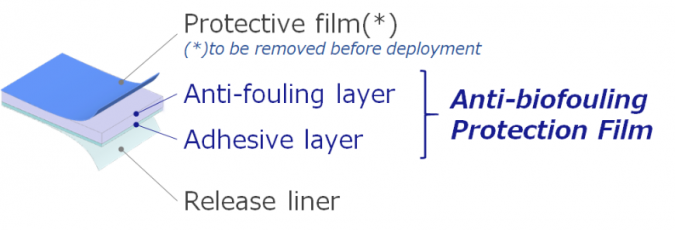

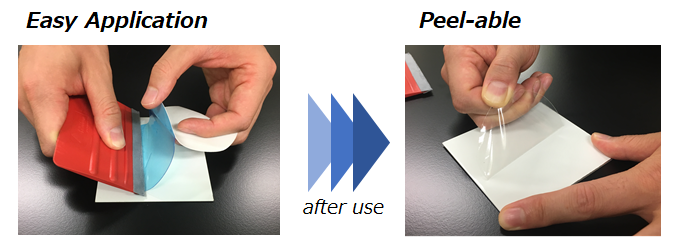

The film consists of four layers: a protective film, an antifouling layer, an adhesive layer, and a release liner (see image). Thanks to the self-adhesive layer, the film does not require any curing time. It can be easily attached by hand and this is all that is needed to protect the instrument from biofouling. The antifouling layer is pre-coated on the film surface. This gives the film a uniform thickness with no significant influence on the accuracy of the results gathered by tested underwater acoustic instruments, while also providing a stable and long-lasting antifouling performance. The special face of the antifouling layer is able to prevent the adhesion of microorganisms’ organic adhesive proteins without any biocide substances. The protective blue layer on the top is used to protect the special antifouling layer from dust, dirt and atmospheric particles and must be removed before the film/instrument is deployed.

After use, the film can be peeled off by hand. There is no need for a high-pressure water jet, scraper, brush or any other tool that may damage the sensitive sensor area or the surface of the instrument.

The results of the anti-biofouling test conducted on different applications are described below.

Antifouling Test on a PVC Panel

MARINGLIDE™ has been tested all over the world and has shown good anti-biofouling performance every time.

As an example, a PVC panel was partially covered with Nitto anti-biofouling protection film and deployed underwater in Mikawa Bay, Japan, for two months. There was no biofouling on the film, but a lot of barnacles attached to and grew on the bare surface of the PVC panel (see Figure 1). When the film was removed by hand, the surface underneath the film was clear and clean, as in its original state.

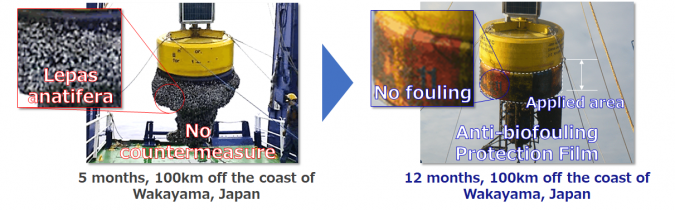

Antifouling Test on TRITON Buoy with Japan Agency for Marine-Earth Science and Technology (JAMSTEC)

Another test was conducted in cooperation with the Japan Agency for Marine-Earth Science and Technology (JAMSTEC). The film was applied to a JAMSTEC TRITON buoy beneath the waterline. The buoy was then deployed 100km off the coast of Wakayama, Japan, for 12 months. The film proved to be successful and considerably prevented biofouling accretion on the TRITON buoy. The result is even more evident when compared with the status of the same buoy deployed for five months without the film, which is fully covered in lepas anatifera (see Figure 2).

Antifouling Test on ADCP with Nortek Japan

The film can also be used on acoustic doppler current profilers (ADCPs). The film was attached to ADCP transducers in cooperation with Nortek Japan, and the transducers were placed in the ocean for four months. The transducers were completely clean, while the surrounding area was covered in barnacles (see Figure 3). The ADCP was also able to gather all the necessary data accurately.

Anti-biofouling for Underwater Camera

There is also the case of underwater cameras, which are used not only for aquaculture but also for ocean surveys. Underwater cameras usually undergo frequent maintenance due to biofouling, which is time-consuming and expensive. We therefore investigated whether Nitto anti-biofouling protection film could prevent the accumulation of marine organisms while keeping the camera visibility clear (see Figure 4). The camera window was covered with the film and the instrument was deployed in Tokyo Bay for three months. The camera was able to take high-resolution images of fish in a pen for at least 45 days with no maintenance, as the film left the window surface completely clear from biofouling (see Figure 4). This suggests that the film is also suitable for underwater cameras.

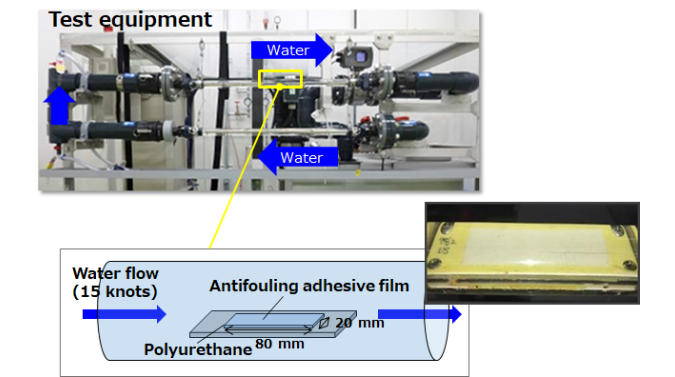

Reliability of the Adhesive Layer

The reliability of the adhesive layer was evaluated by Nitto using special test equipment for water flow resistance (see Figure 5). As a test specimen, the film was applied to a polyurethane panel. The panel with the film was then placed in a plastic tube filled with water. Water flow was generated at 15 knots for 250 hours. The result showed that the film was not peeled off by the water flow. This means that the film adhesive held tight to the substrate, and that it resists ocean currents. Furthermore, no peeling took place even when the film applied to an ADCP was deployed in the Gulf Stream (Gulf of Mexico) for longer than 18 months. This confirms that the adhesive is robust enough to remain in place on long-term deployments and in strong currents.

Get in Touch with Nitto

Nitto designs and develops anti-biofouling solutions for the marine industry and is looking for new applications that require biofouling prevention. Reach out to Nitto today at [email protected] in Europe or [email protected] in North America to discuss the opportunities that anti-biofouling protection film; MARINGLIDE™ could bring to your enterprise.

Value staying current with hydrography?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories from the world of hydrography to help you learn, grow, and navigate your field with confidence. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired by the latest in hydrographic technology and research.

Choose your newsletter(s)