Inevitable Truths of Operating AUVs

A Manufacturer’s Perspective on Routine AUV Utilisation

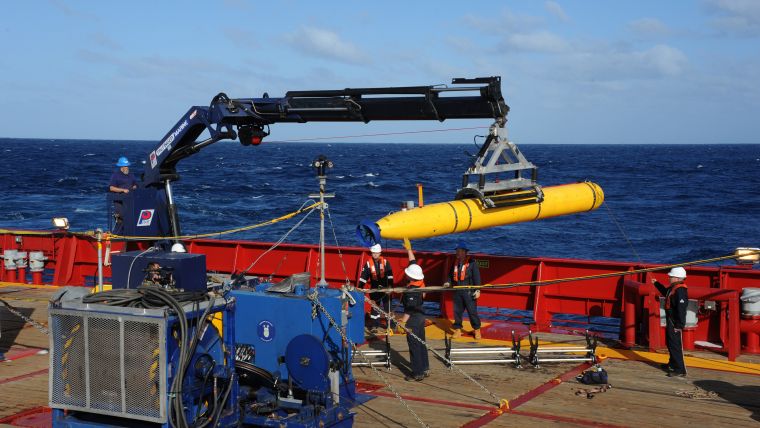

Earlier this year, the US Navy deployed a Bluefin-21 Autonomous Underwater Vehicle (AUV) to search for the missing Malaysia Airlines Flight 370. The tragic disappearance was thought to have occurred over 1,600 kilometres offshore Perth in a remote and very deep region of the Indian Ocean. The AUV was launched 25 times in order to collect over 850 square kilometres of seafloor imagery (Figure 1). As a result, authorities successfully discounted the area as the final resting place of those on board. On-going media coverage offered a glimpse into what AUV operations are really like day-to-day, dive-to-dive. But deploying an AUV starts long before it hits the water.

Having spent nearly two decades demonstrating the capabilities, limitations and tremendous potential of AUVs, Bluefin Robotics have developed an approach to adopting AUVs for successful, real-world implementations. We will outline the realities and challenges of standing up an AUV operation, but more importantly provide key factors worthy of early consideration with the main take away being: success below the surface is a function of preparation done on land.

The Business Case

The first step is to develop a convincing business case that describes the technology, explains how it meets a demand, and outlines monetary potential to stakeholders. A comprehensive evaluation of routine operations is critical, as variables such as crew composition, ship selection and deployment methods can materially impact returns. It is also advisable to highlight how services will be charged - whether it be per trackline, a flat day rate or on delivery of a data product – as these all have different trade-offs. Initial conversations held with manufacturers can help with this step and is critical to establishing expectations and ultimately a specification for the system.

The Selection Process

In order to select the best AUV to meet your business goals, your team should build effective job performance metrics rather than rely on data sheet specifications. Manufacturers can provide practical guidance on how AUVs can meet your objectives. Discussions should focus on your concept of operations including number of vehicles to deploy, op-tempo, typical operational area and depth, required shipping footprint, level of spares, maintenance expectations and plans for upgrades. A factory site visit is very advantageous to learn about AUV potential, develop relationships with technical experts and witness a demonstration.

The Stumbling Blocks

Planning does not end with an AUV purchase. Stumbling blocks can quickly emerge if key areas are not addressed early in the process. At the very least, your team will need to outfit a basecamp facility, source and train personnel, work out shipboard details, plan for infield maintenance and establish a data-processing chain (Figure 3).

Basecamp Facility

A well-designed maintenance facility is just as important for the operator as it is for the manufacturer. As the operator, you should consult the manufacturer to learn what space, instruments and resources are required when the AUV is not mobilised. Does it need test tanks, tools, or packing equipment (Figure 3)? Should the space be flexible for evolving needs or staged for clients demonstrations? Regardless, it should include a healthy IT infrastructure for data handling and vehicle diagnostics, and dedicated areas for battery management, maintenance and logistics.

Education and Training

Investing in a group of capable people should be top priority. Any AUV is only as effective as the team that operates it. Questions include how many people are necessary, what is the ideal skill mix for your organisation, and where will you source these people. Count on your team to develop a vital relationship with the manufacturer during initial years of ownership. Not only will personnel complete system training, but they will also receive on-going education and support to optimise system performance. It is not unusual for personnel to consult the manufacturer’s operations team for advice regarding new operating environments or to strategise anticipated challenges.

Shipboard Concerns

Careful consideration of the type of host ship you plan to operate from will reduce uncertainties during the actual deployment in the field. Planning for various possibilities and building in flexibility will inevitably save you time and money. First, look for any hard requirements such as the available space. How much space will you need? Will you be staged in an ISO container or will you have access to a workspace? Can you recreate a variation of your basecamp facility? What are your options for IT networks, printers and whiteboards, and connectivity to land?

Second, determine what kind of communications and navigation equipment is required and when it can be installed and tested. Some AUVs require simple portable systems, while others have a more integrated approach. If the ship has pre-existing equipment, confirm compatibility and verify it with testing prior to mobilisation. Your manufacturer should be able to assist with this phase.

A launch and recovery plan should be a part of your initial conversations and considerations. Options depend on the AUV, the prospective ship, and the owner’s requirements. If operating from a dedicated ship, a fully-integrated launch and recovery system may be appropriate. If operating from ships-of-opportunity, build in flexibility with an air-shippable docking head. As always, don’t forget to test the equipment in port. An early site visit to the ship can uncover potential roadblocks or inspire modifications to the AUV or auxiliary equipment that can reduce future costs. Sharing photos and schematics can help both your team and the manufacturer.

Interacting with the ship’s crew and other personnel can be challenging if those on board have never worked with or around an AUV. Educating people will be an on-going activity as an AUV operator. Before setting sail, learn whether the captain has worked with an AUV in the past and what their attitude is about the equipment. Understanding who your allies are and then spending time to gain new ones will benefit the job all around and becomes especially important if the ship has multiple objectives.

Infield Maintenance

The type of maintenance paradigm exercised at sea directly impacts short-term and long-term AUV reliability. If technicians are given no choice but to diagnose and repair electronics in the field, equipment can be exposed to the environment injecting risk to the system. It also makes finding a root cause to a failure and implementing fixes back at the factory difficult. As a manufacturer, we promote an approach that enables the greatest reliability for remote jobs in harsh environments. A spares package allows for in field swapping of components and subsystems. The appropriate training and necessary resources can help shift mind-sets towards applying repairs and maintenance at the subsystem level and ultimately increase reliability (Figure 5).

Data-processing Chain

Data is everything when it comes to AUVs. Handling and processing data should be at the forefront of the operation. The type of data required dictates the payload configuration. Future needs should be communicated so that an expansion plan can be designed into the AUV. Questions to ask your team include what file formats you require, what data quality is desired, what is the final data product and what will it look like.

The Dive

It is finally time to put the system in the water and all of the preparation will start paying off. Dive planning can be completed ashore or in the field as needed, but you should adhere to a stringent process to ensure that the system is configured and ready to collect the data. Once on site, pre-dive checks and procedures will confirm that the AUV is ready for work. After the vehicle is launched, the mission starts and the vehicle slips below the waves. Once the mission is complete, your team will recover the AUV, download data and swap batteries. The sequence is repeated.

Conclusion

After you have overcome all the known challenges, you will be freed up to address new issues that arise during the deployment. Possible complications include shipping delays, unanticipated changes to the ship or equipment, personnel changes, inclement weather and adjustments to the search area or job profile. The thing to remember is that challenges inevitably emerge on every job but careful preparation will help in mitigating them and ultimately lead to successful and profitable AUV operations.

Acknowledgements

Many thanks to the good people at Phoenix International who worked with us on their AUV operations.

Value staying current with hydrography?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories from the world of hydrography to help you learn, grow, and navigate your field with confidence. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired by the latest in hydrographic technology and research.

Choose your newsletter(s)