Self-installing Wind Turbines

A Different Approach

The Dutch company SPT developed a new foundation concept for offshore wind turbines in order to reduce the costs and environmental impact: a Self Installing Wind Turbine. The concept is based on a tripod with suction piles. As these foundations do not penetrate as deep as single pile structures, a different approach for survey and soil investigation techniques can be applied.

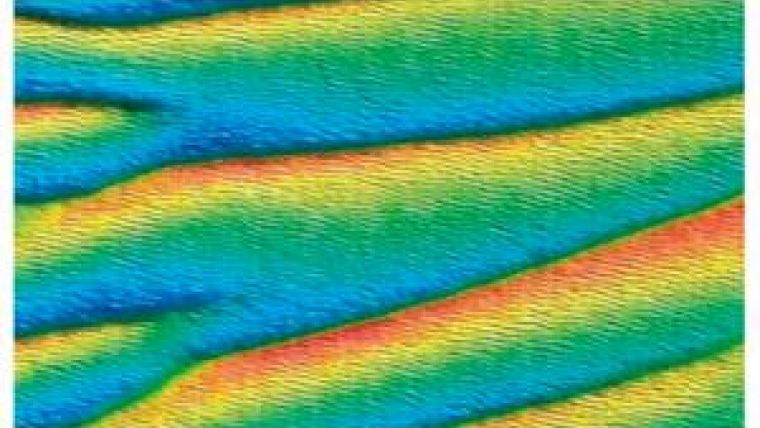

Prior to the design of a wind farm, information on the seabed properties, its behaviour and the underlying geology are required. Insight into the morphology of the seabed by multi-beam (Figure 1), and side-scan sonar surveys (Figure 2) can give information about the seabed dynamics at the proposed site.

Geophysical and hydrographic surveys, including geotechnical investigations, need to be carried out in advance of the design and construction of the piles. An optimal design of the suction piles depends on the soil parameters.

In order to gain more insight into the vertical and lateral changes in the layering (and properties) of the subsurface, a reflection seismic survey can be executed; a single channel seismic survey covering the shallow subsurface (Figure 3) or a multi-channel seismic survey for information on the deeper subsurface. In addition to important lithological information, such as depth to bedrock, occurrence of boulders or the presence of buried valleys and channels, and shallow gas can also be detected.

For the foundation and stability of wind farms and the associated infrastructure, knowledge about seabed dynamics is important. Both short-term and long-term dynamics are relevant. The migration of sand waves may cause short-term changes in the vertical position of the seabed by several metres. Advanced (Fourier) analysis of multi-beam echo sounder data and/or side-scan sonar data will generate numerical insight into the short-term vertical dynamics. This information has to be taken into account when designing the foundation of wind turbines and determining the burial depth for the power cables.

Recent studies have shown that in addition to short-term dynamics also long-term trends in the position or vertical position can be observed, these can we presented in dz/dt maps, showing the vertical trends over time. Over the lifespan of a wind farm these changes can be significant.

Even when no bathymetric time series are available, estimates of the seabed dynamics and trends can be done based upon the general setting of the wind farm.

The vertical trends observed on the Netherlands Continental shelf vary between +/- 0.35 metres per year. In the coastal zones, the trends can be up to 1.5 metres per year. Mainly in areas with tidal channels, breaker bars, tidal inlets, and large scale marine beds, which forms the vertical trends, are the most pronounced (Figure 4).

As the suction piles for the tripod typically do not penetrate deeper than 10 to 15m into the seabed, the main focus of both the geophysical survey and soil investigation can be limited to a depth of 20m below seabed, this is one diameter below the maximum embedment of the suction pile. Both installation and in-place response are suction pile design considerations; the suction piles must be installed to their design embedment below seafloor in order to ensure sufficient in-place capacity to resist combined vertical, horizontal and moment loads. Important geotechnical design parameters are drained friction angles in sandy soils and shear strength of cohesive soils. Penetration analyses are based on CPT results.

The soil investigation will be a combination of both in-situ testing, primarily CPTUs, and borehole sampling. Collection of undisturbed samples and laboratory testing depending on the soil conditions including CAUC, CAUE and DSS cyclic shear tests are required for correlation of CPTU-data, and to determine the build up of the sub-seabed geology and for correlation with the geophysical data collected. For a platform normally one borehole is sufficient plus a CPTU at each suction pile location. The depth of investigation varies from 10-20m for CPTUs and up to 20m for boreholes.

Soil Conditions Dutch Sector North Sea

Most of the geological formations found in the upper layers in the Dutch sector of the North Sea consist of unconsolidated sand deposits with locally clay intercalations and are suitable for the use of suction piles. Other parts of the sector contain extensive clay areas at or near the seabed. Suction piles are also suitable at these areas if the undrained shear strength of the clays does not exceed 150kPa. The North Sea has been a mainly subsiding basin since the Mid Miocene. The hinge line in the South runs more or less in a line from Walcheren, Zeeland, towards the north-west. South of this line Tertiary formations consisting of clay are lying at or near the seabed.

The infill of the basin was a result of extensive deltas building out at first from the east, and fed by former Baltic rivers, and westwardly flowing north German rivers that drained from central Europe. Build-out of the rivers Rhine, Meuse, Scheldt, and British rivers took place in the south and south-west. During the Quaternary Mid and Late Pleistocene sea level dropped significantly several times, and glaciers from Scandinavia and Britain covered large parts of the North Sea and changed the flow direction of the rivers to the south. Along the margins of the ice sheets melt water products such as coarse sand and gravel were deposited. Below the ice cap diamictons, and in the distal area in front of the ice sheet melt water clays were deposited. During the interglacial stages sea level high stands occurred and marine reworking of the deposits took place.

As mentioned above, Tertiary (Eocene and Oligocene) clays occur near or at seabed along the southern margin, with shear strength between 200 and >400kPa. In the south-western part, along the median line between the UK and Dutch sectors in the area of the Brown Bank, brackish to fresh water clays occurred at or near seabed, and were deposited during the end of the Eemian interglacial and the start of the Weichselian, the last glaciation. In this formation shear strengths between 30 and 180kPa have been measured. In the north-western area south-east and east of the Dogger Bank a large area with diamictons and fluvioglacial clay occurs at or near seabed. The shear strength measured varies between 100 and >400kPa.

North of the Dutch islands diamictons occur locally at or near seabed and extend towards the Wadden Sea and the Northern Netherlands. The shear strength varies between 80 and 200kPa.

In fact, the entire coastal area and parts north of the Dutch islands are suitable as location for the Self Installing Wind Turbine.

Scour

As with any offshore foundation located in areas with mobile sediments (e.g. sands, silts) scour holes will develop around the SIWT foundations. The size and shape of these scour holes and the rates with which they will develop are mainly dependent on the hydrodynamic conditions (current velocities, wave climate, water depth), sediment characteristics and the size and shape of the foundation. On the one hand, severe scour is not acceptable due to the limited installation depth. On the other hand, Self Installing Wind Turbines can be designed with a more scour-friendly shape compared to the commonly used monopile. The challenge is to either optimise the design or to come up with innovative scour protection methods as an alternative to the commonly used scour protection consisting of rocks, which requires the use of dedicated heavy installation equipment.

Two Phases

Over the last decade, suction anchors and suction piles are increasingly used by the offshore industry for anchoring floating or fixed structures. The main advantages are: fast and efficient installation (less than 12 hours), accurate levelling (less than 1 degree), cost-effective, reliable design procedures based on extensive international experience, low noise and therefore no distraction to marine life, and easy removal by reverse installation procedure.

A suction pile is a hollow steel pile with a large diameter and a closed top, which is installed in the seabed by pumping water from the inside. The resulting pressure between the outside and the inside is the driving force behind its installation.

The installation of the suction pile consists of two phases. In the first phase, the suction pile is lowered onto the seabed, an opened valve on top of the pile enables water to escape the pile freely. The pile’s weight causes the soil to penetrate into the bottom by gravity. As the penetration depth increases friction starts to act on the pile’s inner and outer sides. At a certain penetration depth the friction forces combined with the tip force will be equal the weight of the pile and penetration reaches its maximum depth. The cylindrical shell that has penetrated into the soil is called the skirt and the final depth is referred to as the self weight penetration depth.

In the second phase, the pump at the top of the steel pile is activated, lowering the pressure inside the pile. The pressure difference between the inside and the outside of the pile results in a downward force over the top of the pile, causing the pile to move downward in the underlying sediments. The installation process affects the horizontal and vertical effective soil stresses and must, therefore, be taken into account during the design process of the suction pile foundation.

The Concept

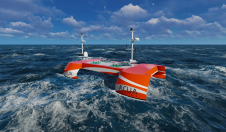

The Self Installing Wind Turbine (SIWT) is a new and innovative foundation concept, enabling complete installation of a full wind turbine (including foundation) in a single operation. This results in earlier power generation of the wind farm and reduces pre-investments.

The complete wind turbine will be assembled in port and subsequently transported and installed from a standard flat top barge (Figure 5). The concept is designed for water depths ranging from 20m to 60m and for wind turbines up to 6MW and higher. The resources required to enable offshore installation are relatively low cost and widely available. The main components of the offshore installation spread are a flat top cargo barge, three tugs, lowering system and suction pumps.

After positioning the barge at the installation site the SIWT will be lowered to the seabed. Upon touchdown and self weight penetration, suction pumps will install the suction piles to the required penetration. This suction operation is accomplished in only 3-6 hours. The verticality and tilt of the structure are adjusted during the suction installation by applying different pressures in the separate suction piles. After successful installation, the lowering system will be disconnected and the suction pumps will be removed (Figure 6).

Decommissioning and removal of the wind turbine is done using the same procedure, but in reverse order. For removing the suction piles, the pump flow is reversed to push the suction piles out of the seabed. No structural elements will be left in or on the seabed. If required, the complete unit can be re-installed at another location.

The SIWT concept has been selected from over 100 submissions by the Carbon Trust for further development. The Carbon Trust is a UK not-for-profit organisation, supported by 7 major utility companies, with the mission to accelerate the move to a low carbon economy. The aim of the study is to select the best concepts for deeper waters and larger turbines and to bring the overall costs down. The study is focused on the UK 3rd round offshore wind farm developments. The design of the SIWT has progressed to a de-risking stage which will be followed by a final design stage which clears the way for installation of full-scale prototypes within 2 years.

In order to reduce the need for jack-ups or drilling vessels, a tailor-made solution of survey, high-resolution geophysics and soil investigation is required. As part of the new concept, a new CPT rig and drilling rig for continuous undisturbed sampling are being developed that can be operated from a standard vessel.

Acknowledgements

The authors are most grateful to T.A.G.P. van Dijk, T. Raaymakers, and C. Laban of Deltares for their valuable contributions concerning seabed dynamics, scouring and geology of the Dutch sector of the North Sea.

Value staying current with hydrography?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories from the world of hydrography to help you learn, grow, and navigate your field with confidence. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired by the latest in hydrographic technology and research.

Choose your newsletter(s)