Hydro Dam Inspection by ROVs

The inspection and maintenance of vital resource facilities is an integral part of any regional health and stability management programme. Providing consistent quality output whilst reducing inspection and maintenance costs is key for those involved in the provision of such services, and requires the monitoring and assessment of relevant new technologies and techniques.

By Rob Berlijn, HydroConsult, The Netherlands

Over the past forty years Remote Operated Vehicles have become a well-proven component of basic toolkits for getting work done under-water in a wide variety of industrial, scientific, military and law-enforcement activities. In many cases the impetus behind adopting and evolving this technology has been to reduce the risks and costs involved in using divers to perform these tasks. In other cases, the ROV is asked to do things that divers were never able to do. The use of ROVs is not new to the arena of hydroelectric dams, but realisation of the full potential of these vehicles is still in its infancy here as compared to in many other industries.

Pricey Divers

The use of divers in the inspection and maintenance of hydro dam facilities is a practice that will remain central to the effective running of these resources, with fully qualified divers carrying out crucial work that cannot be replicated through the deployment of technology. As many will be aware, the cost of such specialist services comes at a premium (up to €1000 per day per diver), with extensive preparations and support facilities required before a diver can actually begin the maintenance aspect of their work. While technology cannot replace the services provided by commercial divers, it can help reduce inspection-related overheads through the deployment of remote, visual-inspection vehicles.

ROV ‘Dive Buddy’

Entering the water before the diver, the ROV is used in a number of ways to aid diver and work effort as a whole. Before a diver or dive-team can begin inspection work the dive must be planned and mapped, helping to ensure the safety of the dive in this hazardous environment. Without the use of an ROV this mapping is done by the dive-team and charged accordingly. Use of the ROV means the mapping can be done without a man entering the water, thus cutting costs and increasing the safety of the team by removing the need to dive in unmapped waters. With high-resolution digital video recording technology ‘onboard’, the ROV relays the submerged environment to the top-side in real time, giving clarity of vision in limited surroundings beyond that of the human eye. Real-time recording allows the dive-team to replay and reassess the dive site before finalising the dive plan and map, again increasing the safety of the man in the water.

The same technologies used to plan and map the dive are employed to reduce the costs of inspecting the fabric of the facility. High-resolution digital camera/video can be used to visually inspect for corrosion and structural damage, the small size of the ROV allows access to areas beyond the reach of divers: pipe interiors, culverts etc., allowing more comprehensive site inspection. Another advantage to using ROVs in this manner is that while divers are exceptionally well trained in their area of expertise, they are not engin-eers. Footage of the inspection site can be played back to qualified engin

eering professionals, thus ensuring the most comprehensive of inspections, and as yet no one has entered the water (or charged the facility for doing so).

The time has now come for the diveteam to do what they do best: operate safely and productively in potentially hazardous environments. Viewing the ROV footage means divers are pre-warned about possible danger areas in attending to the required maintenance, plus they now have an extra ‘set of eyes’ in the water watching their backs. The ROV makes a great ‘dive buddy’, with the real-time image feedback allowing the top-side members of the team to keep a watchful eye on their colleagues, while site facilitators can assess the work in progress.

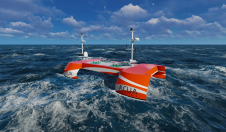

AC-ROV

This scenario will not be new to many readers but, as mentioned, it is the responsibility of facility managers to remain appraised of new technologies within their field of operation. Some may have concerns regarding the full accessibility of a site to an ROV and full operating system. This is not an issue for the next generation of inspection-class ROV technologies: with the full system contained in a hand-carry-size case and the required power supplied via a small portable generator the complete package can be deployed and controlled by one person. The AC-CESS-built AC-ROV is one such technology, a new inspection-class ROV. Employing five degrees of movement, the ROV has the flight pattern of a helicopter, as opposed to an aeroplane; this means the unit can hover and fully rotate on its axis, it moves as fast sideways as it does forward or backwards. In inspection terms, it can sit directly in line with the target object, rotate around the target and move closer or pull away while not turning the camera away form the target.

ROV Use Example

An example of successful use of ROVs for dam inspection is the Rock Island dam-inspection programme. Mitigating the effects of cavitation pitting of hydroelectric turbine blades requires regular inspections.

This is traditionally accomplished by de-watering an entire generating unit to below the turbine.

Typically this can take a unit offline for two to four days, significantly affecting availability and revenues. Chelan, of Washington (USA), working closely with Deep Ocean Engineering, Inc. (DOE), has led the way to achieving substantial savings through the utilisation of ROV technology to perform the inspections without de-watering and reduce unit outages to less than four hours. When Chelan first contacted the ROV manufacturer to discuss the feasibility of performing the desired inspections

using an ROV it was determined that the application called for one of the more powerful models in order to achieve the long penetrations involved in reaching the Kaplan turbines from downstream. The dimensional constraints imposed by the bulb-type turbine inspections of the Rock Island dam further limited the choices to an HD2+2.

This vehicle has in its standard form four thrusters for forward motion, a lateral thruster and a single vertical thruster. With the long, upward excursion needed to reach the Kaplan turbine blades in mind, an extra vertical thruster was added in the position normally occupied by the camera and its tilt mechanism. Because of the need to inspect all of the areas in the confined spaces around the runners, a special pan/tilt mechanism was installed forward of the normal camera position. Two additional cameras were added to complete the suite of video capabilities.

A pair of lasers mounted parallel to the primary camera and spaced exactly ten centimetres apart gave the ability to scale an object in view at various distances.

A trailer was used to house and transport all the ROV system, including the vehicle, control consoles, umbilical, transformer, tools, safety equipment and spares.

The control consoles are secured to a bench in their operating positions, with all the connections already in place. The trailer is thus rapidly converted from storage and transport unit to ROV

control centre. Heating and airconditioning are built in for year-round operations.

Kaplan Turbines

This ROV system was delivered in 1998 and was sucessful in completing the desired inspections right from initial deployment. The main tasks given the ROV were cavitation inspections, trash-rack inspections and survey of erosion in the spillway at Rocky Reach. The savings realised in these early operations paid back the acquisition costs within the first year. In 2000 and 2001 the savings were over three times the investment to date, which included another round of upgrades.

Even with these exemplary results, there was room for further operational improvements that would further enhance returns on investment. The method devised for inspecting the Kaplan turbines of the Rocky Reach dam from downstream made use of one of the four stop-logs that would normally be used to close off the draft-tube outlet. This was now used as a platform to carry the ROV down to the opening of the draft-tube. A simple aluminium stage was fabricated to give the ROV a measure of protection from the turbulence of the tailrace during descent of the launch phase and recovery-phase ascent.

This stage also provides a fairlead for guiding the ROV umbilical from the long vertical drop into the draft-tube. It is secured to the top of a stop-log.

The ROV trailer is set up at about ten metres above the water on the tailrace deck, next to the gantry-crane used to raise and lower the stop-logs. Once the stop-log reaches the bottom of its journey, the vehicle is flown off the stage and down to the bottom of the draft-tube floor. From there the pilot sets the vehicle down on the bottom and uses the sonar to confirm the location and heading, then proceeds up the draft-tube whilst keeping in contact with the floor.

Following the floor the pilot will see a steady increase in depth readings, and then the depth will begin to decrease as the tunnel gradually transitions from horizontal to vertical. Once the vehicle reaches the height of the runner, the inspection is completed. The method of inspecting the bulb-type turbines at Rock Island dam differs fundamentally from the Kaplan, in that the turbines are accessed from the upstream side through the head gate-slots. The trailer is set up on the intake deck and the water level in the head gate-slot is close enough to deck level to allow a simple launch using a small crane and a simple hook on the vehicle’s lift point.

Using the stop-log downstream of the turbine stops the flow through the unit. The wicket gates are opened to their fullest extent and the turbine runner is ideally stopped in a position such that the gaps between the wicket gates and the gaps between the turbine blades line up. The ROV is piloted from the bottom of the head-gate slot into the scroll case and through the wicket gates and turbine blades into the draft-tube.

Since the area of most interest on these horizontal axis turbines is also on the downstream side of each of the blade tips, the vehicle needs to pull enough umbilical down below the runner to manoeuvre around its full circumference. This is accomplished by driving some distance down the draft-tube and doing a U-turn to come back to carry out the inspection.

Another Challenge

The long horizontal penetration and vertical ascent up the draft-tube for the Kaplan inspections presented a challenge even with the added

vertical thruster. Working inside a dam with significant vertical flows is an unusual set of conditions rarely encountered by ROVs within other environments. While all ROVs need to ascend and descend efficiently, pulling their umbilical upward while pushing their largest cross-section through the water against a downward flowing current is not what they are typically designed to do! The wicket gates are closed to minimise the flow, easily done from the control room, but they are often not able to stop the flow completely. In most cases it was necessary to set head gates in order to reduce flow sufficiently for the inspection to be carried out. This adds considerably to the time that each unit is offline for inspection, and to the labour costs of each cycle.

Heavy Payloads

Another area where the capabilities of the ROV were stretched was in the amount of equipment or payload carried. With three cameras, a pan-and-tilt mechanism, sonar, lasers, a manipulator and the extra vertical thruster, it was necessary to provide added floatation. All of these externally mounted items added considerably to the drag through the water. The inherent stability of an ROV, which comes from having a high centre of buoyancy and a low centre of gravity, tends to suffer as the weight of the onboard equipment pushes designed-for payload limits. Stability makes an ROV easier to pilot and greatly enhances its efficiency as an inspection platform.

Preach and Practise

After several years of successful, cost-saving operations, Chelan and DOE entered into discussions about designing a custom-ROV that would specifically address the enhancements that operational experience showed would improve performance. DOE designed and manufactured a custom-ROV for this application that has substantially improved performance for both types of turbine inspections. It features four vectored thrusters for manoeuvrability in the horizontal plane, and three vertical thrusters to overcome downward currents in the long upstream penetration of Rocky Reach’s Kaplan units. The hydro-

dynamics of the vehicle were emphasised throughout the design process, but particular attention was given to the drag experienced by ascending through a downward current.

A Smart Zoom Colour Camera and an ROS Navigator low-light camera are mounted on a Sidus Pan/Tilt.

This arrangement provides a greater range of camera views as compared to the previous arrangement. A rear-facing camera and another camera that can be positioned as needed provide a highly versatile set of tools for visualising the condition of the turbine blades. Parallel lasers mounted on the Pan-and-Tilt provide the ability to accurately scale pits or other damage through the imagery provided by the cameras and recorded to videotape/DVD.

A Fiber Optic Gyro (FOG) is installed to give the pilot an accurate heading despite an adverse magnetic environment that prevents typical flux-gate compasses from being any use at all. This heading data, along with vehicle pitch-and-roll and camera pan-and-tilt position, plus water temperature, are

displayed and recorded as a programmable overlay on the video, with DOE’s On-Screen Display (OSD). An Imagenex 881A multi-frequency sonar for navigation and obstacle avoidance and a Manipulator round out the list of standard accessories integrated on this vehicle.

The powerful vertical thruster array, combined with the vehicle’s refined hydrodynamics, have proven capable of performing routine inspections without the time-consuming installation of head gates, even where the wicket gates allow substantial flow through the turbine. This has allowed the ROV crew to complete back-to-back unit inspections within the four-hour outage window originally intended

for a single inspection. Overall savings are being realised from the lower cost of performing inspect-ions and improved revenues from reducing the time the generating units are offline. In addition, the versatility of the ROV has enabled various other underwater tasks in and around the dam and lake-areas that would otherwise have been done by divers at higher cost and greater risk.

Chelan has successfully taken a bold initiative in utilising an ROV in a previously untried application within the hydroelectric industry, proving that there are significant rewards to be realised by doing so. Using this approach for both Kaplan and bulb-type turbines has great potential at other sites. There are, no doubt, many other potential tasks that could benefit from the advances made in ROV technologies and techniques in this and other industries.

Value staying current with hydrography?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories from the world of hydrography to help you learn, grow, and navigate your field with confidence. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired by the latest in hydrographic technology and research.

Choose your newsletter(s)