Rethinking the Traditional Model for Offshore Operations

A Bright Future Ahead for iXblue’s New USV

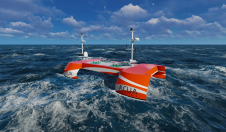

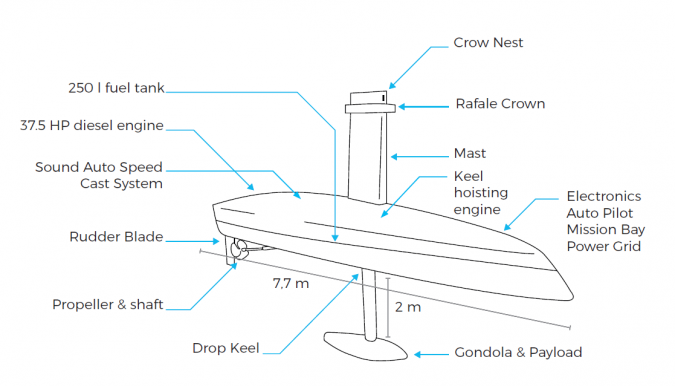

Back in May 2018, the conspicuous red hull of DriX, iXblue’s new unmanned surface vessel (USV), could be seen sailing the waters of the Caspian Sea. Hidden from view, 2 metres below the surface, the iXblue acoustic synthetic baseline positioning system called Ramses was performing a highly accurate rig positioning operation for Total E&P, the world’s fourth-largest oil & gas company.

(This article is brought to you by iXblue)

A global leader in the design and manufacturing of innovative solutions dedicated to the offshore Energies, Ocean Science and Defence markets, iXblue was contracted by Total E&P to conduct this box-in operation using DriX, a new revolutionary platform enabling more flexible and reliable offshore operations such as subsea tracking, positioning and monitoring.

Rig Positioning Operation

Total E&P was looking to trial new solutions on the highly-competitive offshore market by reducing the time needed for operations such as the box-in of its wellheads, while still acquiring excellent and highly accurate positioning information. The Oil & Gas company needed a solution that could offer more flexibility compared to using the more costly vessels already busy conducting other operations and that might not be available when needed.

“Total E&P was looking for a flexible and cost-efficient solution to conduct a specific rig positioning operation off the coast of Baku, Azerbaijan” explains Olivier Cervantes, vice-president Marine Services at iXblue. “Right after we launched DriX, Total E&P saw the high potential of our new USV. Coupled with Ramses acoustic positioning system, it truly offers offshore operators a revolutionary platform to conduct their operations with flexibility, saving both precious vessel time and money with no compromise on data quality or safety”.

DriX and its operating team left their home port in La Ciotat, France, and traveled all the way to Baku, Azerbaijan, for this mission aiming to provide highly-accurate positioning of the rig’s wellhead at depths of 500 metres, for future drilling operations.

A first series of tests was carried out by the iXblue and Total E&P teams in the Port of Baku, before the transit of DriX on the supply vessel Jura, to the rig location, 100 kilometres off the coast of Baku.

Precise Positioning Data

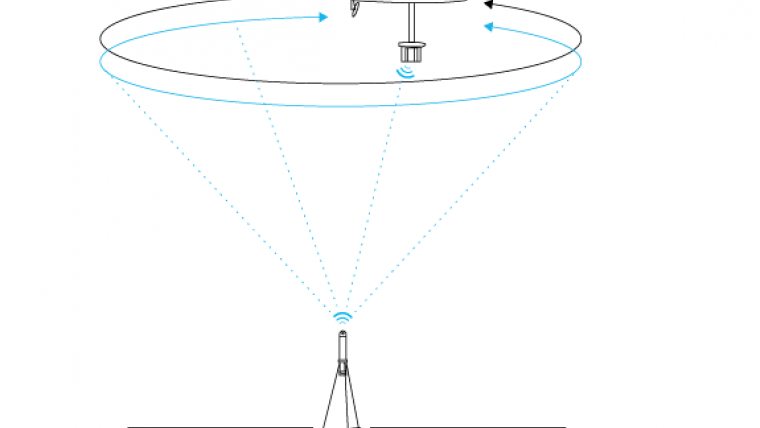

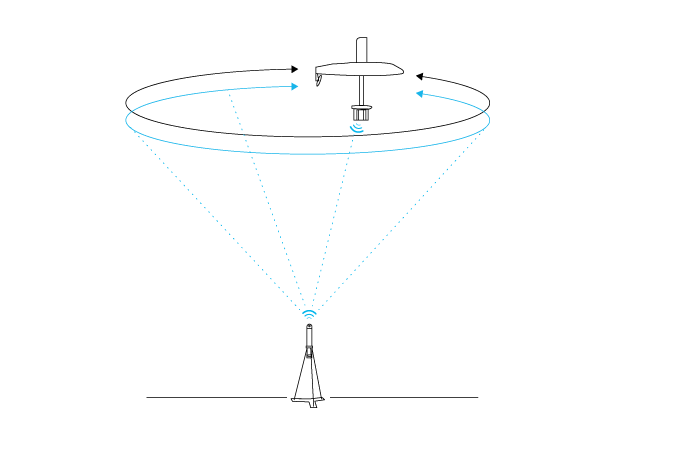

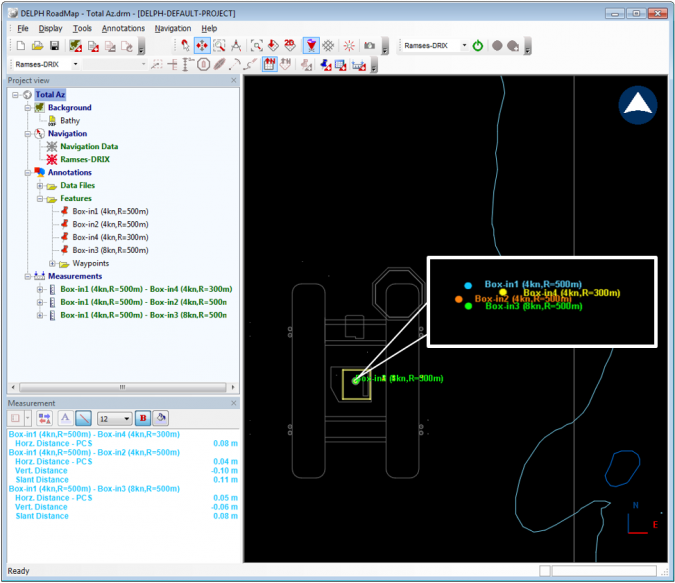

The box-in operation itself was then carried out by DriX and Ramses Long Baseline (LBL) and a sparse LBL intelligent transceiver that precisely measures the distance to the transponder previously installed on the wellhead. In order to acquire precise positioning data, DriX was positioned over the transponder and performed circles of both 300 and 500 metres radius in opposite directions. By doing so, Ramses was able to measure accurate distances from various angles and could then compute the precise average position of the transponder.

In less than 3 hours total time on site, where traditional box-in operations usually last from 6 to 10 hours, four box-ins were conducted on the same drill point. The data collected by DriX and Ramses proved to be excellent, showing better than <10cm dispersion between all positions produced and comparing extremely well to the Total E&P average USBL reference position of 1.5 metres.

Thanks to the DriX wave piercing shape that keeps the slamming effect to a minimum to ensure the utmost stability of the platform and to the USV’s gondola, located in an optimum data gathering environment, 2 metres below the surface, in noise-reduced and bubble-free surroundings, the mission was able to be successfully conducted at speeds of up to 8 knots, or twice as fast as traditional data-acquisition methods.

Reduced Amount of Data

The operation duration was also significantly reduced thanks to the smaller diameters of the circles that DriX had to perform around the wellhead. Indeed, most acoustic positioning companies, which determine the diameter size according to the depth at which the transponder is located, would have had to perform circles of 1 kilometre in diameter for a 500-metre depth and acquire a minimum of 800 ranges. Defined years ago, these operational constraints are commonly recognised as providing suitable mitigation against the effect of cumulated noise sources coming from GNSS, acoustics or heave etc.

However, thanks to GNSS accuracy, Ramses ranging and INS precisions, combined with perfect control of mechanical mounting, these sources of uncertainty were greatly reduced on DriX, ultimately reducing the amount of data required to converge to decimetre performance over the water column and hence lowering operational constraints of the box-in mission.

‘’Overall, this trial made with iXblue using their DriX and Ramses was a real success” states Frédéric Auger, chief surveyor at Total E&P. “I am convinced that this new technology developed by iXblue will bring high benefits for future survey and positioning works’’.

During this test with Total E&P, four box-ins were successfully conducted, all of them producing repeatable positions whatever DriX speed (up to 8 knots) or circle radius (300m or 500m), the fastest one taking less than 17 minutes whilst perfectly matching all other results.

High Accuracy Box-in Techniques

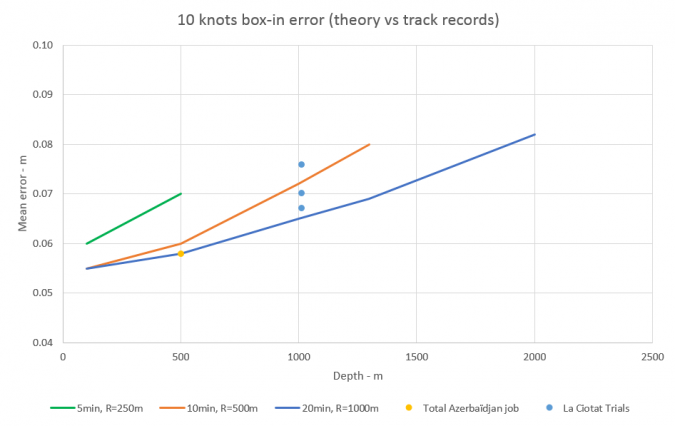

Achieved calibration time and precision at a speed of 8 knots opens extremely interesting perspectives of high-accuracy box-in techniques being applied in real-time for pipe-lay and touch-down monitoring operations, providing decimetre accurate positions of ROVs whatever the lay back or the water depth. The following graph illustrates the possibility for surveyors to evaluate the positioning accuracy they can expect from a fully equipped DriX for TDM operations, depending on their operational constraints such as water depth and pipe-lay vessel speed.

From the above grid, for example, a pipe-lay vessel working in a 1000m offshore field, and with a limit of 10 minutes for average fixes on quad-joints, can expect, with DriX, better than 10cm positioning accuracy without having to deploy any transponder on the seabed, thus saving several days of operation over a typical pipe-lay campaign.

With DriX, iXblue offers offshore operators a revolutionary platform that disrupts the traditional model for subsea operations by providing a cost-efficient, reliable and flexible solution and was able to impress Total E&P during its trial in Azerbaijan. Along with the global Oil & Gas company, other offshore operators have shown great interest in DriX, promising a bright future ahead for iXblue’s new USV.

Value staying current with hydrography?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories from the world of hydrography to help you learn, grow, and navigate your field with confidence. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired by the latest in hydrographic technology and research.

Choose your newsletter(s)