Securing Offshore Oil and Gas Infrastructure with USVs

While the exigencies of climate change have led to major strides in the development and deployment of renewable energy sources such as solar, wind and others, the world’s energy needs will continue to be met primarily by oil and natural gas for the foreseeable future. As readers of Hydro International are well aware, the strategic implications of the United States’ transition from energy dependence to energy independence to becoming a net oil and gas exporter are being felt worldwide. While some saw this sea change coming, most did not, and the community of nations is still coming to grips with what this will mean to the energy market over the next several decades.

Offshore Oil and Gas Industry

While much of the reporting regarding America’s increased energy production has focused on fracking – which has opened up billions of barrels of oil and trillions of cubic feet of natural gas to production and transformed the global energy sector in a matter of a few years – it is the offshore oil and gas industry that still provides a huge amount of the United States’ energy. According to Forbes Magazine, offshore energy production has been increasing over the past decade and now stands at over two-and-a-half million barrels of oil and almost three trillion cubic feet of gas a day.

This massive production effort is sustained by the hundreds of US offshore drilling rigs, primarily in the Gulf of Mexico. According to Forbes Magazine, the Trump administration has directed the Department of the Interior to open up 25 regions in the outer continental shelf to oil and gas exploration. Indeed, in February 2019, Phase 3 of the Atlantis Project commenced in an effort to create a tie-back of eight new production wells. There is little question that the United States intends to accelerate its harvesting of oil and gas in the Gulf of Mexico as part of the Trump administration’s America-First Offshore Energy Strategy.

Industry Disasters

However, environmental concerns – impelled by major events such as the 2010 Deepwater Horizon disaster in the Gulf of Mexico – have served as a brake on US offshore drilling. And it is worth noting that the second-largest marine oil spill in history, the Ixtoc 1 spill, also occurred in the Gulf of Mexico. These – and other industry disasters – have resulted in ongoing environmental activism that has given some second thoughts about the viability of continuing to drill for oil and gas offshore.

Addressing these environmental worries has been a challenge for the oil and gas industry. And while offshore oil and gas companies have been proactive in ensuring the safety and viability of their platforms, more remains to be done. Using current technology, this is dull, dirty and dangerous work that impedes comprehensive inspections of these production rigs. Today, platform operators depend on divers and remotely operated vehicles (ROVs) of various types to perform these inspections. This methodology is good as far as it goes, but ROVs have a limited field of view and putting divers in the water always involves substantial risk and increasingly high costs.

The industry has proposed technology-enabled solutions that can provide faster and more thorough inspections of these enormously expensive platforms and insure against not only catastrophic disasters like Deepwater Horizon but also more common issues like wear and tear of underwater components – to say nothing of potential sabotage of these oil and gas rigs by terrorists or environmental activists. And much like an iceberg, what the eye can see above the water when viewing an oil or gas rig is only part of the story. There is a tremendous amount of the infrastructure that is below the surface and unseen.

Canal and Dam Hydrography

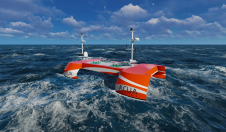

Maritime Tactical Systems, Inc. (MARTAC), a Florida-based manufacturer of unmanned surface vehicles (USVs), has deployed a family of low-cost, rugged and adaptable MANTAS USVs built on a catamaran hull. Part of the attraction of using USVs such as these for offshore oil and gas platform inspections is that they have had extensive use in military exercises, experiments and demonstrations in both near-shore and open-ocean operations, as well as hundreds of hours of use in a number of civilian missions, ranging from commercial canal and dam hydrography to commercial power plant inspections to port and harbour security.

The MANTAS T12 (12-foot) USV has already been equipped and tested with a wide variety of surface and below-surface sensors, such as the SeaFLIR-230 Gyro-stabilized High Definition EO/IR zoom camera with laser tracking, FLIR M232 thermal camera, Teledyne RESON T20 high-resolution multi-beam sonar, Teledyne BlueView M900 single-beam echo sounder and Norbit iWBMS STX multi-beam sonar, among others. MARTAC already has a T24 (24-foot) and T38 (38-foot) MANTAS in the final design for fabrication. Later this year, MARTAC will introduce its first T38 as an operational USV in a major international military exercise.

Off-the-shelf Technology

This off-the-shelf technology can be used today to effect faster and more complete inspections of offshore oil/gas platforms, along with their surrounding bottom-mounted pipelines, valves and sensors, while dramatically decreasing the need for human divers. Under this concept, a MANTAS USV would be controlled by one operator in the Rig Command Centre. This inspection of bottom valves, vertical pipes, fittings, pipelines and other rig components can be part of scheduled, routine checks or be done on-demand to investigate something out of the ordinary discovered by Rig Command Centre watchstanders.

Three primary missions where the Rig Command Centre would utilize this USV concept include:

- For underwater imaging, the MANTAS (T12, T24 or T38) could be equipped with Norbit iWBMS STX multi-beam sonar, a forward-looking or side-scan sonar, or any of many other commercial off-the-shelf underwater sensors.

- For surface investigation, which would include area security, external rig structure investigation and surface contact monitoring, as well as other missions that a MANTAS USV is ideally suited for, the MANTAS could be equipped with a SeaFLIR-230 or FLIR Cutlass-240 Gyro-stabilized High Definition EO/IR zoom camera, or alternately a simpler FLIR M400, M500 or M625CS.

- Since one of the early indicators of material failure of oil rig components involves oil and other material from the rig seeping into the surrounding water, the MANTAS USV can be equipped with water-monitoring sensors to include Acoustic Doppler Current Profilers (ADCP), Current-Temperature Depth (CTD) sensors, fluorometers and others to detect changes in the water quality in the immediate vicinity of the rig.

On-station Loitering Endurance

While the size of the MANTAS T12 restricts its ability to carry multiple sensors (surface and subsurface), the T24 and T38 have that inherent capability and sensor-swap modularity. Additionally, the endurance of the T12 is currently restricted to batteries and solar panels. The T24 and T38 are diesel-powered, thereby providing a significant extension to their missions and on-station loitering endurance. The selection of the T24 and/or the T38 for this mission would, therefore, be the optimal solution.

Depending on the mission, operators in the Rig Command Centre can control any of the mentioned USVs remotely and direct their missions manually, or use them in an autonomous or semi-autonomous mode to search along a predetermined course, through the use of pre-programmed waypoints. Most significantly, the video and sonar imaging from the MANTAS can be sent directly to the Rig Command Centre in real time, thereby providing immediate notification of what the USV discovers above or below the water surface, and enabling operators and management to make time-sensitive decisions regarding rig operations.

Anticipating near-term demand from the offshore oil and gas industry, MARTAC is developing concepts of operations (CONOPS) for how MANTAS would be used to help ensure rig security. For example, an operator in the Rig Command Centre might have a MANTAS on patrol on a predictable pattern, inspecting the rig above and below water. If the USV discovers an anomaly and links the video back in real time, the operator will be alerted, can switch to remote manual control, and can command the MANTAS to linger in a particular area for more granular analysis.

If this investigation uncovers an area of concern, then a diver can be deployed to make a repair. Clearly, this CONOPS will secure the integrity of the rig, while also substantially reducing the false alarms generated by other methods. Conversely, if the investigation does not reveal an issue, the MANTAS can return to its previously programmed autonomous mission profile.

Critical Infrastructures

The same USV technology that is poised to assist the oil and gas industry is already being used to inspect critical infrastructures such as harbours, ports, inland waterways, dams, levees, canals, bridges and other infrastructure that cannot be safely or effectively inspected by humans. For example, a MANTAS USV was used to conduct inspections of the Keokuk dam and energy centre, the Bagnell energy centre, the Elkhart hydro dam, the Central Arizona Project canal and other infrastructure.

Oil and gas rigs in the Gulf of Mexico, while not necessarily bunched together, are in some areas close enough for several rigs to share a single MANTAS. With a cruise speed of 20 knots, burst speeds of up to 80 knots for the larger craft, and a cruising radius of 60-plus nautical miles, several rigs can share one MANTAS USV. This scheme can be particularly valuable as it could well result in sharing best practices among various oil and gas companies where, if a USV discovers that a valve, fitting or other gear on one rig is in need of repair or replacement, operators can perform more frequent inspections of that component on other rigs.

Commercial Off-the-shelf USVs

The enormous investment that the United States’ energy companies have made in their offshore oil and gas rigs is one that these companies must protect from failure, sabotage or other hazards. Protecting these expensive and vulnerable rigs is a first-order priority for the industry and one that is increasingly expensive. Current means of inspecting these rigs are slow, expensive and hazardous. Employing commercial off-the-shelf USVs like the MANTAS T24 or T38 that can be rapidly reconfigured with a diverse range of sensors can enhance the ability to deliver energy to the US and the world. This is a win-win for the energy industry.

Value staying current with hydrography?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories from the world of hydrography to help you learn, grow, and navigate your field with confidence. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired by the latest in hydrographic technology and research.

Choose your newsletter(s)