Optimizing Multibeam Deployment to Improve Survey Mobilization Capabilities

This technical webinar, presented by Subsea Europe Services GmbH, details new techniques for configu...

With an extensive portfolio of technology, services and expertise designed to help every organisation collect and evaluate marine data on their own terms, Subsea Europe Services GmbH makes it easy to access and use precision sensors and equipment, complete survey systems, cutting-edge unmanned and autonomous platforms and innovative, unifying solutions.

The company’s unique ‘systems, service, solutions’ capability is enabled through partnerships with leading technology innovators including AML Oceanographics, BeamworX, BeeX, MARTAC, R2Sonic, Seatronics and Sonardyne, ensuring availability of the best tools for on-demand and planned marine surveys anywhere in Europe on a rental, sales or uniquely, a subscription basis.

While serving a diverse customer base, from offshore wind farm owners and contractors to hydrographic survey companies, government organisations and research institutes, Subsea Europe Services continues to create new developments that simplify and automate the collection of marine data.

Innovations include the cutting-edge Autonomous Surveyor, which is one of the most advanced Autonomous Surface Vehicles (ASV a.k.a. USV) available for marine survey applications in the world. In parallel, Subsea Europe Services offers the unique A.IKANBILIS Hovering AUV, a new AI-powered solution capable of smart thetherless operation for offshore wind farm and other underwater inspection applications.

Subsea Europe Services has also developed the unique integrated Hydrographic Survey System (iHSS), an easy-to-configure, deploy, and operate system for high-quality marine data acquisition. Simple to install and operate on dedicated survey boats and vessels of opportunity, the iHSS demonstrates Subsea Europe Services’ strength as a unique hydroacoustic systems integrator.

Subsea Europe Services systems, services and unique turnkey survey solutions harmonise sensors, systems, platforms and expert support. Possible through close collaboration with technology, USV and AUV manufacturers, the complete solutions that Subsea Europe Services creates are part of a new generation of technology driving the industry towards more autonomous, cost-effective and environmentally friendly marine surveying.

This technical webinar, presented by Subsea Europe Services GmbH, details new techniques for configu...

Find detailed technical information about the Autonomous Surveyor USV - based on the MARTAC MANTAS T12 platform and view brochures, videos and case studies and...

Find detailed technical information about the Sonardyne Mini-Ranger 2 and view brochures, videos and case studies and compare it with other similar products

Find detailed technical information about the R2Sonic Sonic 2020 Multibeam Echosounder and view brochures, videos and case studies and compare it with other sim...

Find detailed technical information about the Integrated Hydrographic Survey System (iHSS) and view brochures, videos and case studies and compare it with other...

Find detailed technical information about the R2Sonic Sonic 2024 Multibeam Echosounder and view brochures, videos and case studies and compare it with other sim...

Find detailed technical information about the R2Sonic I2NS Type I or Type II and view brochures, videos and case studies and compare it with other similar produ...

Asset availability and efficiency is essential to reducing non-productive time in marine operations. But things go wrong. An essential and expensive custom tool may be lost over the side of an OSV during a wind turbine installation. An anomaly in previously acquired data could make it too hazardous to continue a cable installation. The list of potential reasons for downtime is endless and to some extent, so is the cost. Which is why getting marine survey capabilities on-site quickly is one of the most important aspects of restarting operations.

Urgent projects

Often referred to as ‘gap-filler’ surveys, these projects are usually defined by the need for industry standard multibeam solutions with little notice prior to the day of the survey. This demands a certain flexibility in the logistics chain, which too often isn’t available. Even clearly urgent projects can be forced to wait due to equipment not being available locally or even in the same country. And while vessels and crews are waiting to restart work, costs continue to increase.

Rapid survey

Marine Survey Company Nicola Engineering GmbH was tasked by an offshore wind company to carry out a ‘rapid survey’ to locate and identify a small feature on the seabed near an offshore wind farm in the North Sea. Understanding the need to deliver data quickly, rather than wait for a large, slow commercial survey vessel to become available in the area, Nicola Engineering turned to Dutch shipyard and workboat charter company ProMarine BV to mobilise a fast survey boat, and Subsea Europe Service for the survey technology needed.

Small, far-away

While deploying urgently was the main priority, bringing together a cost-effective solution which met the needs for conducting a short survey far from shore was particularly challenging. The solution was to deliver a pre-configured integrated Hydrographic Survey System (iHSS) for installation on a high-speed vessel, which would be capable of significantly reducing the transit times, and therefore the cost of the survey. The approach sounds simple, but the complexity of procuring, installing and operating hydroacoustic technology has always slowed down the rapid deployment of vessels of opportunity for urgent jobs.

Game-changer

But the Subsea Europe Services’ iHSS is a game-changer. As a fully integrated, ready to mobilise all-in-one system it has lowered the bar for entry on survey technology. It’s simple and very fast to install and calibrate, and can even be operated by less skilled personnel. Able to acquire data to the new IHO S-44 Exclusive Order standards, it includes everything needed; R2 Sonic 2024 or 2020 multibeam echosounder, workstation, software, I2NS inertial navigation system and flexible mounting. Uniquely, the iHSS has an all-in-one pole mount design with multibeam, Inertial Motion Unit and GNSS antennas in one reference frame, which simplifies installation further and reduces potential errors from inconsistent or wrong offsets, contributing to the iHSS’ ability to deliver data of the highest quality.

Offshore outcome

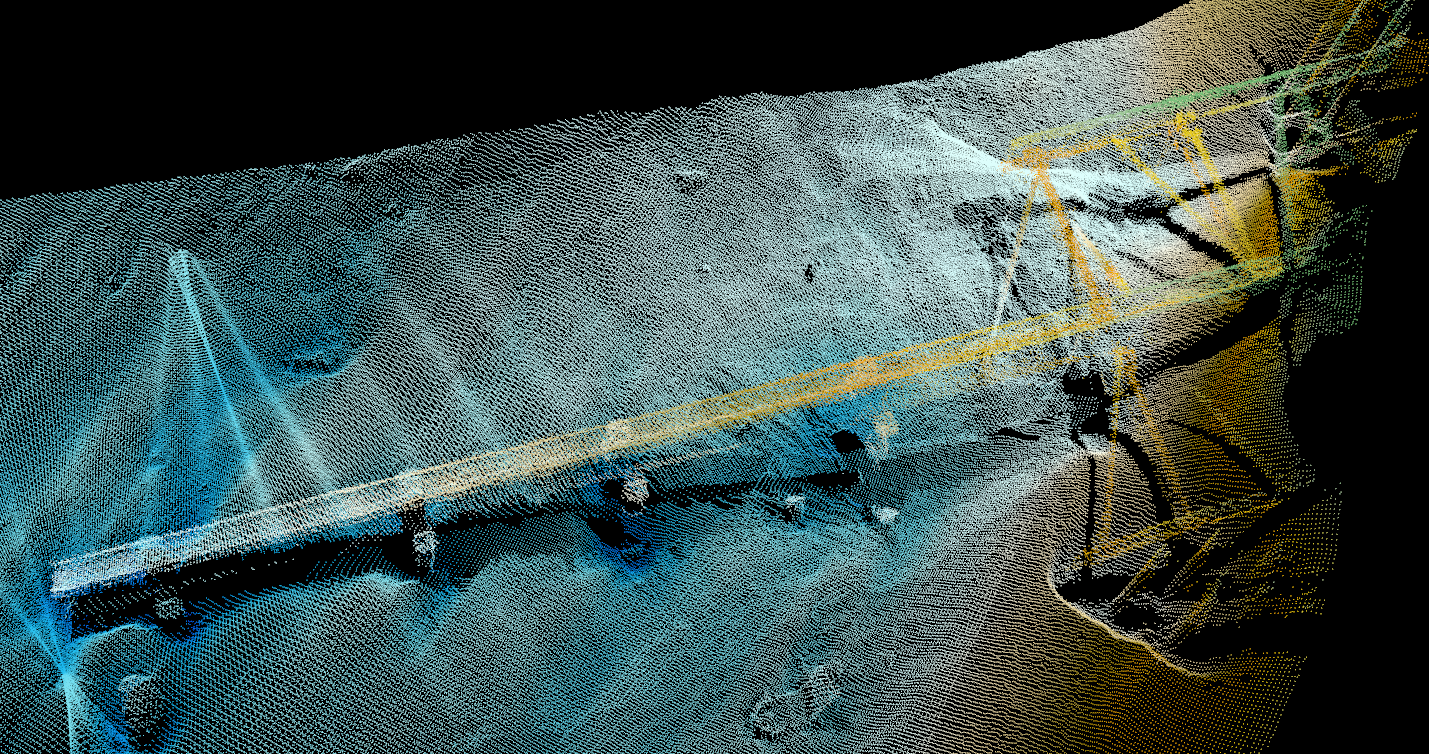

The combination of the quick deploy iHSS, a class approved survey boat with offshore permits in place and skilled operators met Nicola Offshore’s requirement for an ad-hoc high resolution multibeam echosounder survey of a small subsea feature approximately 1 m in length in water depths exceeding 30 m. The data was acquired within two days of Nicola Engineering receiving its brief and the survey, including transit was completed in a single day out of a small port in the Netherlands. Mobilisation and calibration of the whole system took about 2 hours and the iHSS successfully located and identified the feature faster and at a considerably lower cost than using a commercial survey ship. Ultimately, without the availability and simplicity of the iHSS, putting together the right solution for this project would have taken much longer and cost much more.

This site uses cookies. By continuing to use this website, you agree to our Cookies Policy. Agree