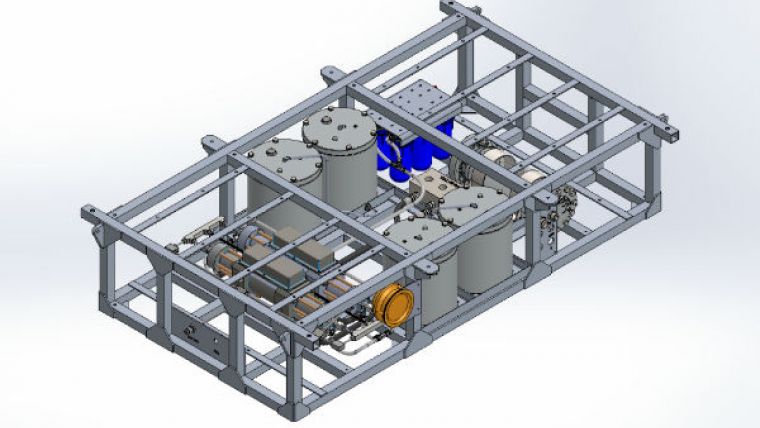

Deepwater Waterjet Cutting, Blasting System for Work Class ROVs

Chukar Waterjet, USA, introduces its SUB-JET 3000 subsea waterjet system for work class ROVs. Operable at depths up to 3,000m (10,000 feet), the SUB-JET 3000 cuts steel up to 250mm thick and blasts away coatings, corrosion and marine growth at pressures up to 3,900 bar. Because it is deployed with an ROV, the SUB-JET 3000 is less expensive than a standalone subsea waterjet system.

The requirements for an independent launch and recovery system (LARS), umbilical, and subsea hydraulic power unit (HPU) are eliminated, resulting in a system acquisition cost of about 20 to 30 percent of a standalone system.

The 100hp SUB-JET 3000 produces 7.5 litres per minute of 3,900 bar ultra-high pressure water for cutting and blasting. It carries 35 litres of abrasive on the skid standard, which provides 30 and 90 minutes of cutting time.

The ROV provides hydraulic oil to power the waterjet intensifiers and operate attached tooling, 24VDC (300W) for control power, and a fibre optic data link to the topside controller. The system requires between 150 and 200 litres per minute of hydraulic oil to run at full capacity but can be operated at lower output if the auxiliary oil is not available from any given ROV. Cutting and coating removal are still effective at lower UHP output, only at slower throughput rates. The system weighs about 500kg on the deck and is neutrally buoyant with 35 litres of abrasive.