Unmanned Technology Narrows Data Gap of the World’s Most Sediment-laden River

With a total length of 5,464km, the Yellow River is the second-longest river in China. Its middle section runs through the Loess Plateau, where it picks up sand and dust, making it the most sediment-laden river in the world. Yellow River runs through nine Chinese cities and affects the daily lives of tens of thousands of people who live alongside the river.

To better protect the ecology of the watershed, monitoring changes in the underwater terrain and studying the pattern of river evolution can provide important data to support river management and flood control. However, technical limitations and harsh environmental conditions mean that the Yellow River watershed has not yet been mapped accurately. The water system is complex, with rapid currents and many shallow areas, making it difficult to install survey equipment using traditional measurement methods and to find a suitable workboat. Operations on the water also pose high risks to personnel.

Unmanned Technology Solution

Not long ago, the Second Topographic Survey Team of the Ministry of Natural Resources used intelligent equipment such as unmanned aerial vehicles (UAV) and unmanned surface vessels (USV) to carry out integrated, multi-element topographic surveys in the Qiankun Bay section of the Yellow River.

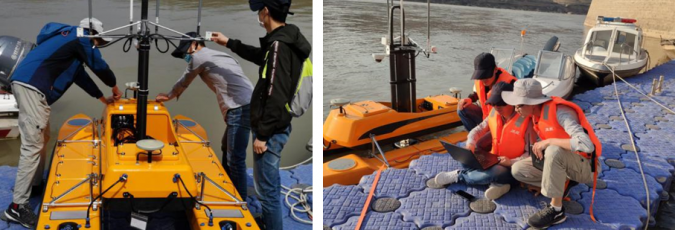

The underwater topographic survey was carried out using OceanAlpha’s ME120 autonomous surface vessel platform equipped with a multi-beam sounding system. The ME120 USV adopts a modular design with three sections that can be quickly assembled and disassembled. It can work automatically and sail into areas as shallow as 0.45 meters. These advantages make it well-adapted to operations on complex waters.

The transducer and sound velocity meter of the multi-beam system was installed in the lifting mechanism of the USV. Through the USV shore-based control base station, the lifting mechanism can be remotely controlled to raise or lower the wet end equipment. There is therefore no need for personnel to remain on board for retracting operations. The lifting mechanism reduces the risk of equipment damage and better guarantees the safety of personnel.

Using the real-time measured water depth and multi-beam span, the surveyor set up parallel survey lines and inspection lines with the base station software from the dock. The USV navigated according to the survey line instructions and the collected data was sent back to the shore-based control terminal in real time.

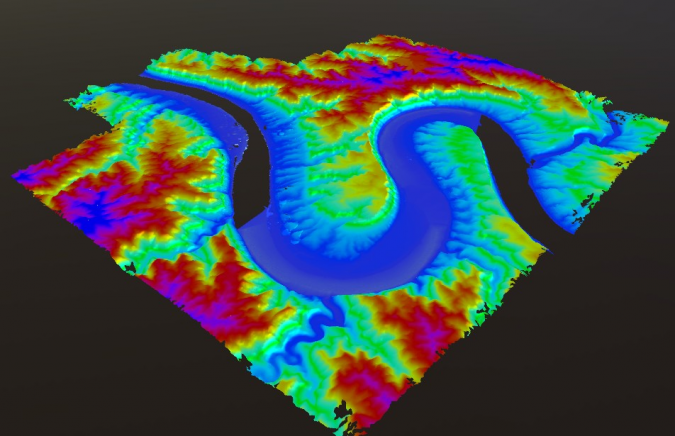

Survey Result

The collected data delivered high-quality, clear reflects of the topography of the river. The ME120 USV was also equipped with a high-precision inertial navigation system, which provides strong support for the seamless splicing of multi-beam data and UAV data. After analysis and processing, the team obtained high-quality integrated above-water and underwater data of the Qiankun section.