An oil slick was seen on the surface of Nootka Sound and staining on rocks of nearby Bligh Island, west of Vancouver Island, Canada, in late 2020. This set in motion an emergency operation to identify the source of the pollution and plan measures to protect the local ecosystem. Canadian authorities contracted the Resolve Marine Group, which requested Trondheim-based Norbit to perform a technical assessment. Norbit’s U.S. partner Seahorse Geomatics executed the contract.

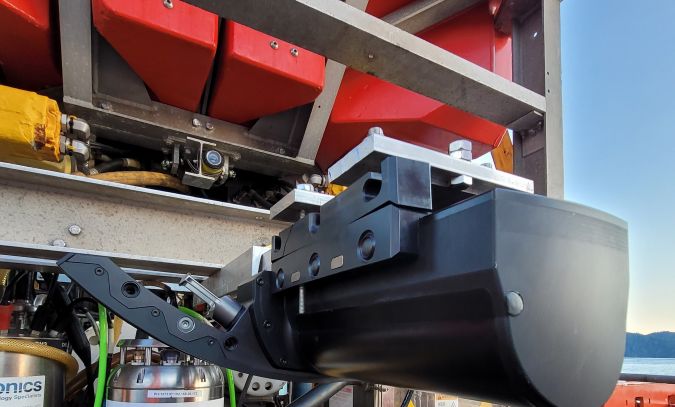

The key objective was to make a rapid and accurate determination of the source of the diesel and oil that had appeared on the ocean’s surface. The company carried out hydrographic survey work using a Norbit Winghead i77h multibeam echosounder (MBES) system. The team deployed the device both from the surface, mounted onto a small rescue-type craft, and underwater, from a Helix remotely operated vessel (ROV) model XLX 66.

ROV Equipment Installation

On the ROV, the Norbit Winghead i77h was installed alongside a Norbit compact high-resolution forward-looking sonar (the WBMS-FLS) and various sensors for ROV navigation and positioning purposes: a VERIPOS LD5 integrated sensor positioning system, an iXblue Phins Subsea inertial navigation system (INS) (for ROV position, true heading, attitude, speed, depth and heave) and a Kongsberg HiPAP 501 acoustic positioning system.

Multibeam Sonar to Detect Subsea Leakage

MBES technology has wide applicability in subsea leakage detection. The technology uses acoustics (sound signals) to build up maps of underwater space. This leaves the underwater environment undisturbed, which is particularly important in situations of hydrocarbon leakage. The Norbit Winghead, launched in mid-2020, is a unique curved-array ultra-high-resolution bathymetry sonar system utilizing the latest in analogue and digital signal processing.

The Norbit Winghead is versatile, easy to use and optimized for rapid mobilization on any platform. It offers a 0.5° x 0.9° beam width at 400kHz and a HD beamformer providing 1,024 beams per ping. The system’s low power consumption means that it can be battery operated. It provides a simple ethernet interface and signal processing capabilities, including roll stabilization, water column and backscatter output. The Norbit Winghead system offers maximum signal-to-noise ratio and ultra-high resolution via an 80kHz FM signal – the widest available in the industry – and long pulse lengths, providing maximum energy.

The ability to capture water column and backscatter data in addition to bathymetry is an advantage of multibeam sonar when detecting and classifying oil spills. The intensity of the sound echo reflected back to the sonar transducer provides information about features in the water column. These can be as detailed as fish, plumes, gas bubbles or pockets of viscosity.

Mapping a Historic Shipwreck

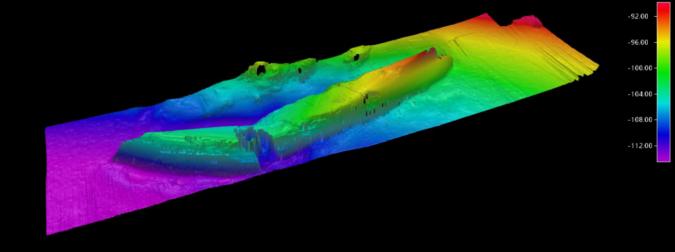

In this case, multibeam surveys confirmed the source of the diesel and oil as leakage from the MV Schiedyk, a 147m cargo ship that sank in these waters more than 50 years ago, in 1968. The shipwreck remained some 106–122m below the surface, too deep for divers. An estimated 60 tonnes of diesel and heavy fuel oil were still in the hull.

The bathymetric surveys showed the ship resting bottom-up on the seafloor. The multibeam images also revealed plumes of oil travelling through the water column. With these, responders were able to pinpoint specific areas of leakage from the hull that could not be captured by video surveys. Importantly, the images showed that the vessel was leaking from more than one area.

Versatility, Ease of Mobilization and Installation

Equipment versatility, ease of mobilization and ready installation are important considerations in operations such as this one. This is where the Norbit Winghead really showed its added value. The team mounted it first onto a small rescue-type craft to conduct bathymetric surveys from the surface of the water. They then mounted it onto the ROV for the subsea operation.

Data Acquisition and Processing

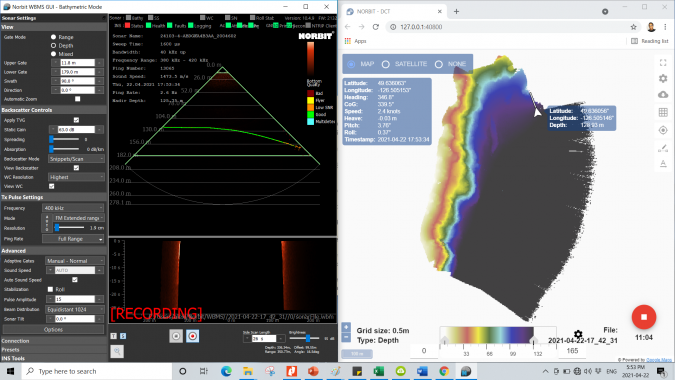

For data acquisition during the survey work carried out from the surface, the team relied mainly on Norbit’s graphical user interface (GUI) and DCT data acquisition software. The DCT software displays the general bathymetry grid in a web browser. This allows the operator to readily assess coverage and data quality in real time while running the survey. DCT offers four displays: depth, standard deviation, sounding density and backscatter. Operators can operate or toggle between these views using a touch screen on a navigation plotter, tablet, smartphone or PC.

For the surveys using the ROV, the data acquired from the equipment was streamed topside via ethernet to a PC that was additionally running the QPS Navigation and Positioning Software (QINSy).

Showcase of the Strengths of the Norbit Winghead System

This use case, in Nootka Sound, was a showcase of the strengths of the Norbit Winghead system. The technical assessment team needed an echosounder system that was ultra-high resolution, to accurately reveal the places where the ship wreckage was leaking so that temporary seals could be applied to reduce the release of oil where possible. The system also had to be reliable, robust and quick to mobilize, as weather conditions could not be known in advance. Finally, a versatile system was needed, as in addition to the bathymetric surveys from the surface vessel, closer-range ROV survey work had to be done to gain a fuller picture of the MV Schiedyk’s condition and risks to the environment. Particularly, the existence of oil in the various tanks had to be confirmed, their locations mapped and any obstacles to oil removal identified.