Dynamic Laser Scanning Set to Innovate Metrology Techniques

In December 2016, DOF Subsea (DOF) conducted a demonstration of dynamic underwater laser scanning as a replacement for traditional metrology techniques at The Underwater Centre in Fort William, Scotland. The demo showcased 2G Robotics’ and Sonardyne’s complete dynamic survey solution.

The solution integrates 2G Robotics’ underwater laser scanner, the ULS-500 PRO, with Sonardyne’s inertial navigation sensor, SPRINT; Syrinx DVL and 6G acoustics. Seatronics, channel partner for 2G Robotics and provider of Sonardyne rental equipment, provided sensors and project/technician support.

LBL and Photogrammetry

Historically, metrology campaigns using Long BaseLine (LBL) acoustics and photogrammetry have demanded significant vessel and ROV time. Additionally, LBL requires physical interaction with the subsea assets and photogrammetry is unable to provide real-time results. The goal of the demo was to quantify the reduction in operational time and increased accuracy of dynamic laser scanning for subsea metrology.

Metrology Methodology

Two structures each containing four flanges were placed on the seafloor with an approximate baseline distance of 18m. The control measurement for the analysis was established by an LBL acoustic technique with flange orientations provided by installed gyro frames.

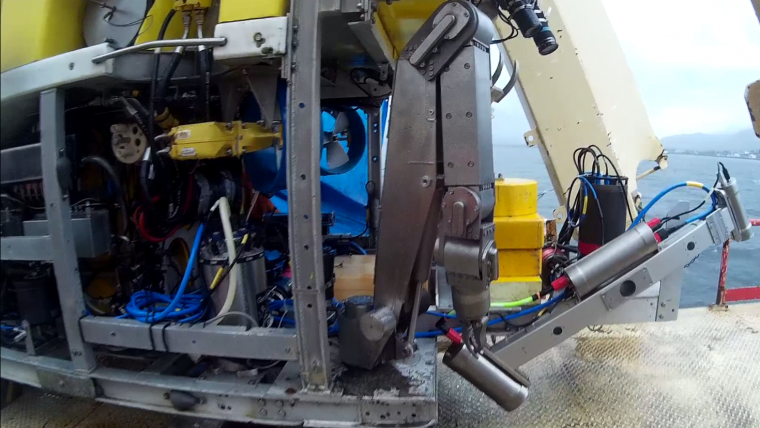

A Triton XL ROV was fitted with complete dynamic survey solution from 2G Robotics and Sonardyne. The ULS- 500 PRO was mounted at 30° to capture the side facing hubs, upward facing hubs, and seabed in a single scan pass over the 18m baseline. With each scan run taking only 4 minutes, the ROV performed multiple redundant runs from structure-to-structure at an altitude of approximately 3m.

Real-time Data

The data was transmitted to the surface in real-time, processed through EIVA navigational software, and then through DOF’s Metro Prep software for automated metrology analysis. From these high-resolution point clouds, exact measurements were taken to facilitate the fabrication of spools and jumpers while concurrently providing as-built condition assessments. The measurements of the vertical jumper metrology and the horizontal spool metrology were within accepted industry tolerances.

Survey Results

- Reduced Survey Time - Significant reduction in the time to gather the data when compared to other techniques.

- Real-time Data - Delivery of final metrology measurements offshore within hours of data acquisition.

- Contactless - No physical interaction with assets is required.

- Flexible Deployment - Configurable mounting orientations on ROVs for specific survey applications

- More than Metrology - The 3D model used for metrology serves as an As-Built model of the subsea installation and the surrounding area to provide a baseline for future intervention work.

Value staying current with hydrography?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories from the world of hydrography to help you learn, grow, and navigate your field with confidence. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired by the latest in hydrographic technology and research.

Choose your newsletter(s)