Enhancing safety and data processing efficiency

A group of companies recently came together to conduct an offshore multibeam survey of the anchorage near the entrance to Boston Harbor using an autonomous vessel. The surge in autonomous survey vessels in recent years is understandable, as they reduce the risk of injury to personnel and crew fatigue while enabling operations in conditions where crewed vessels may be unable to work. The entire survey was conducted in just over two hours, including data processing. The survey turnaround time was reduced by automatically transferring collected data in time-limited packets to a remote processing team while the survey was being conducted.

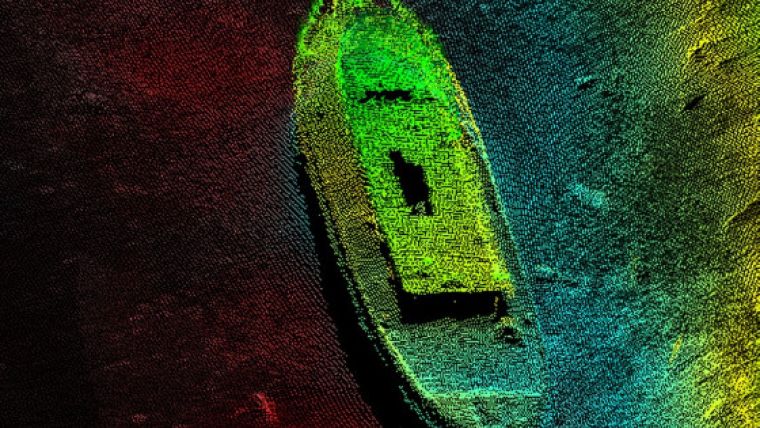

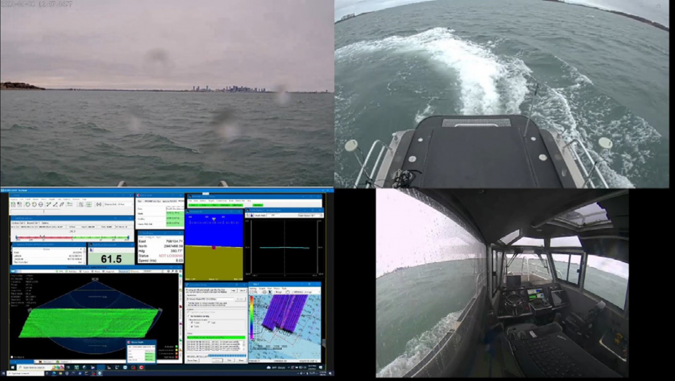

Sea Machines provided the vessel, which was controlled by its SM300 Autonomous Control System. The vessel was commanded and monitored from the Sea Machines control room in Boston. Connectivity is always important in remote operations, so 4G internet was used for the survey. Such a strong connection to the vessel enabled real-time streams from the vessel cameras, radar and AIS, making situational awareness feasible. In the office, the assortment of displays allowed the operator to simultaneously monitor multiple views. Survey Equipment Services provided the survey sensors with on-site installation assistance from Gary Sayers throughout the project. A Teledyne T20 MBES and an Applanix POS MV were used for the survey.

The main challenge to address was how to collect, process and turn a survey around as quickly as possible using the autonomous platform. To facilitate this, the 4G internet connection provided access to the onboard computers. A lot of time and attention was spent setting up the system to upload a survey directly from the vessel, since the sooner the data was available to operators, the sooner the survey could be viewed and a decision made about its quality.

In many cases, the data collected during a survey can only be processed once the vessel returns and the data can be offloaded. For this survey, the data was collected on one PC then transferred over an internal network to a network storage device accessible to anyone on the network. However, a key issue was the size and amount of data uploaded over the internet connection.

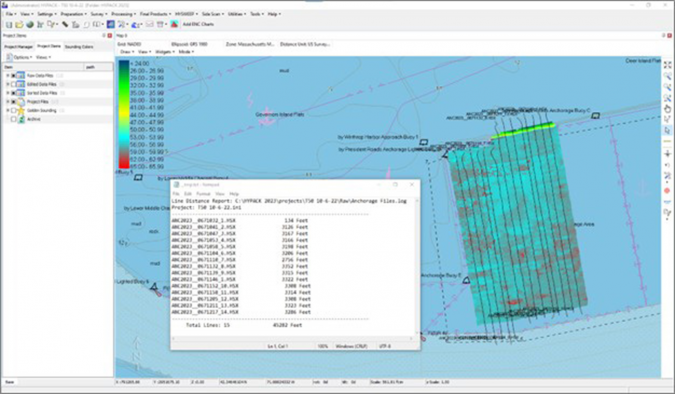

HYPACK® software was configured to create a new file every 15 minutes of survey. Having the 15-minute limit on files controlled the size of the collected data to a manageable amount for transferring over the network or even off the ship. The size of the files can be reduced for lower-bandwidth situations. Once a file reached its 15-minute limit, it was closed and transferred across the network for processing and a new file was opened to continue data collection. The transferred file was processed onboard the vessel by the remotely located OARS team. This method reduced the amount of time between file close to processed sonar data ready for use.

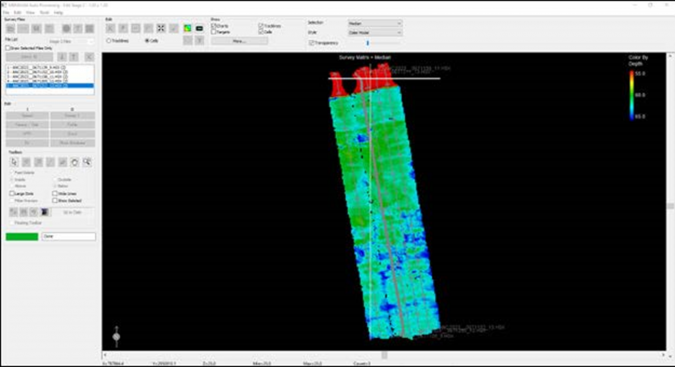

Using a sync programme to synchronize two computers, the data can be transmitted off the vessel to a cloud storage location and onto the appropriate office node that is synched to the cloud storage. Meanwhile, in the office, the HYPACK 64-bit Multibeam Editor (MBMAX64) can be run in Auto-Process mode to apply filters and save the processed data without human interaction.

While all surveys require human monitoring for safety and QC, the tasks of collecting and processing a survey can be extensively automated. In this collaboration with Sea Machines, setting up the autonomous vessel to automatically send packets of data to be remotely accessed allowed the simultaneous processing of data, increasing personnel safety while cutting down the turnaround time.

Value staying current with hydrography?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories from the world of hydrography to help you learn, grow, and navigate your field with confidence. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired by the latest in hydrographic technology and research.

Choose your newsletter(s)